- Classification: chemical auxiliary agent

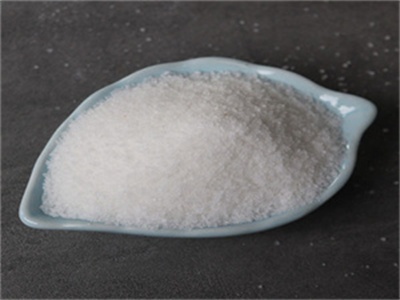

- Appearance: off-white granular powder

- CAS No.:9003-05-12832

- Type: cationic,nonionic

- Formula: (C3h5no)N

- Solid Content: 89~90%

- Application:sewage water treatment industry

- Transport Package: 25kg kraft paper bag

- Delivery: 3-7day

preparation of cationic polyacrylamide suspension and its

cationic polyacrylamide (cpam) solid particle is one of the most commonly used organic polymer flocculants in oilfield wastewater treatment, but it poses some problems, such as a slow dissolution rate and an easy formation into a “fish-eye” in the process of diluting into aqueous solution. however, the current liquid cpam products also have some problems, such as low effective content

biopolymer-based flocculants a review of recent technologies,biopolymer-based flocculants have become a potential substitute for inorganic coagulants and synthetic organic flocculants due to their wide natural reserves, environmental friendliness, easy natural degradation, and high material safety. in recent years, with more and more attention to clean technologies, a lot of researches on the modification and application of biopolymer-based flocculants

polyacrylamide in wastewater treatment applications

in practical applications, the type and dosage of polyacrylamide can be adjusted based on the different requirements of wastewater treatment processes. moreover, by optimizing polyacrylamide product formulations for specific industries and wastewater treatment scenarios, its performance in specific application fields can be improved.

understanding polyacrylamide (pam) types,polyacrylamide (pam) is a water-soluble linear polymer and one of the most widely used water-soluble polymer compounds.its derivatives find applications as efficient coagulants, thickeners, paper enhancers, and liquid friction reducers across various industries, including water treatment, papermaking, petroleum, coal, metallurgy, geology, textiles, and construction.

application in oilfield wastewater treatment

wastewater treatment process, restricting the improvement and innovation of the process. in recent years, researchers have begun to study the preparation technology of liquid cationic polyacrylamide products [17–19], but there are still many technical difficulties to

the best 10 packaging manufacturers in durban 2024 africa,sho-pac. address: 555 mountbatten dve, reservoir hills, kwazulu natal, 4091, south africa, durban. see full address and map. categories: packaging manufacturers

preparation of cationic polyacrylamide suspension and its

solid particle cationic polyacrylamide (cpam) is one of the most commonly used organic polymer flocculants in oilfield wastewater treatment, but there are some problems, such as slow dissolution

flocculating agents manufacturer and supplier water.biopolymers like chitosan are emerging as eco-friendly flocculants due to their biodegradability and effectiveness in binding contaminants. process optimization : in industrial applications, such as the brewing industry, flocculation is crucial for the fermentation process, affecting the quality of the final product.

application of polyaluminum chloride-polyacrylamide as new

natural organic matter (nom) is easily soluble in surface water and difficult to be removed thoroughly. in this paper, polyaluminum chloride-polyacrylamide (pacpam), as a new water treatment material, was proposed to solve this problem by coagulation treatment. the performance, mechanism and kinetic process of nom removal were investigated systematically. results showed that the optimum

polyacrylamide pam industrial chemical raw materials,high quality high molecular weight polyacrylamide (pam) is commonly used as a flocculant in water and wastewater treatment, as a soil conditioner, and as a viscosity modifier low cost

flocculant companies in south korea chemicals raw materials polyacrylamide

nox korea has developed hes-plus, a high-speed coagulation sedimentation method,.request quote established in 2002 to become the best in environmental field,nox korea as an environmental design’s specialized construction enterprise, has acquired patent for developing equipment which reduces atmosphere non-point pollutant source through

9003-05-8 polyacrylamide sale from quality suppliers,cas 9003-05-8 polyacrylamide products & prices & suppliers. polyacrylamide is relatively stable to heat with its solid only being softened at 220~230 °c and its solution subjecting to significant degradation only at above 110 °c. polyacrylamide is insoluble in benzene, toluene, xylene, gasoline, kerosene, polyacrylamide flocculant fuel, but soluble in water.

polyacrylamide pam suppliers, manufacturers, factory good

polyacrylamide (pam) is the collective name of acrylamide homopolymer or polymer copolymerized with other monomers . polyacrylamide (pam) is one of the most widely used varieties of water-soluble polymers .

a contemporary review on plant-based coagulants for good price,seeds of p. vulgaris constitute of an anionic protein-type coagulant fraction. chromatographic separation of the water-soluble extract of plant seeds using amberlitetm ira 900 cl was carried out by antov et al. that shows the coagulant fraction to comprise of predominately negatively charged amino acids.

natural versus synthetic polymers for wastewater treatment

metal ions such as calcium ions could play a crucial role in the adsorption of anionic polymers on particles of similar charge despite electrostatic repulsion. in this ion binding scenario, the positively charged ca 2+ ions act as bridges between the negatively charged particles and the anionic groups on the polymer chains. encapsulation systems

welcome at aece egypt the apparel export council of egypt,apparel export council (aec) is a non-profit organisation established by ministerial decree no.207. it is a public-private partnership (ppp) between the polyacrylamide of trade and industry and an assembly of the most prominent apparel exporters. (+202) 25656036 (+202) 01000756728. info@aecegy.com

china polyacrylamide suppliers, manufacturers, factory

cationic polyacrylamide. the pam products was produced by adopting unique process “pneumatic drying”, the granularity can be controlled between 80-140 mesh, it has the unique features of slimsy granule, rapid solution ,.