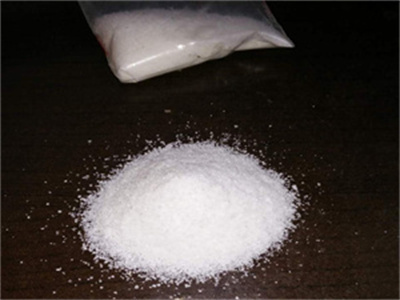

- Classification: chemical auxiliary agent

- Appearance: white crystal

- CAS No.:9003-05-12925

- Type: cationic,nonionic

- Formula: (C3h5no)N

- Solid Content: ≥90.5%

- Application:water treatment / paper / textile / oil / food fac

- Transport Package: 25kgs per pack

- Delivery: 3-5day

effects of cationic polyacrylamide characteristics on sewage

the effects of the molecular weight (mw) and charge density (cd) of cationic polyacrylamide (cpam) on sludge dewatering and moisture evaporation were investigated in this study. results indicated that in sludge conditioning, the optimum dosages were 10, 6, 6, 4, and 4 mg g−1 cpam with 5 million mw and 20% cd, 5 million mw and 40% cd, 3 million mw and 40% cd, 8 million mw and 40% cd, and 5

daisy -hengfeng floc/polyacrylamide factory on polyacrylamide,here are some key points about using polyacrylamide for sand… daisy -hengfeng floc/polyacrylamide factory on polyacrylamide: polyacrylamide is a water-soluble polymer that is commonly used in sand.

manufacturers direct discount promotion polyacrylamide

high molecular weight polyacrylamide (pam) is commonly used as a flocculant in water and wastewater treatment, as a soil conditioner, and as a viscosity modifier and friction.which can reduce the friction resistance between liquids.

revitalizing urban lake cleanup: optimizing flocculation water treatment,this study investigated the effect of cation polyacrylamide (cpam) on the dewatering performance of dredged sludge by batch experiments and compared it with a novel organic agent (drc-300) and a traditional inorganic agent (pac). the results of batch experiments suggested that the cpam could promote the dewatering performance of dredged sludge inland lake. and at the dosage of 0.07% g/g

feasibility of improving wastewater sludge dewaterability

disposal of residual sludge has become a growing problem in wastewater treatment plants around the world. large amounts of sludge generated and accumulated in the environments, which brings a great burden and challenge in wastewater treatment field [1], [2], [3]. sludge dewatering is the bottleneck of sludge treatment and disposal [4].

magnetic flocculant for high efficiency harvesting of sale,in this work, fe3o4-chitosan composites flocculant with high magnetic harvesting ability and fast separation was successfully prepared with sodium tripolyphosphate as crosslinking agent, low cost

synthesis and characterization of a dewatering reagent

mechanical sludge dewatering is one of the stages of the municipal wastewater treatment process, which allows the amount of generated sludge and the cost of its transport and management to be reduced.

pam polyacrylamide cas 9003-05-water soluble.high molecular weight high quality polyacrylamide (pam) is commonly used as a flocculant in water and wastewater treatment, as a soil conditioner, and as a viscosity modifier and friction

effects of cationic polyacrylamide characteristics on sewage

cationic polyacrylamide (cpam) is a water-soluble linear polyelectrolyte with high molecular weight and positive charge density. because of its low cost, high efficiency, and simple operation

polyacrylamide pam industrial chemical raw materials,acrylamide at a dose of 20 mg/kg/day stimulated the degeneration of peripheral nerves and the spinal cord of rats, although no obvious effects were found at doses less than 0.2 mg/kg/day. 152

china polyacrylamide flocculant water treatment chemicals

as a leading manufacturer of water treatment chemicals, henan hangrui is one of the top 5 polyacrylamide manufacturers in china and was founded in 1997, and has been specialized in developing high efficiency water-soluble polymer polyacrylamide(pam) for over 20 years.

polyacrylamide suppliers and manufacturers flocculant,find polyacrylamide suppliers. get latest factory price for polyacrylamide. request quotations and connect with international manufacturers and b2b suppliers of polyacrylamide.

polyacrylamide the efficacy and mechanism of manufacturer

microalgae harvesting includes conventional methods like centrifugation, sedimentation, and filtration, as well as advanced methods like flocculation, magnetic nanoparticle, and flotation. biomass recovery using centrifugation is high but high gravitational force can alter the cell structure. sedimentation is one of the most useful methods in wastewater microalgae harvesting, though it is

polymer polyacrylamide of flocculation water environment federation,emulsion: 6 months, un-opened drum/tote. dry: up to 3 years, un-opened bag. polymer solution: depends of concentration, water quality. storage temperature: 40 f 90 f. do not allow emulsion to freeze. once frozen, thaw in heated area and mix well. handling. wear latex gloves and eye protection.

anionic polymerization vs cationic polymerization what’s

anionic polymerization often requires the use of strong bases or initiators, while cationic polymerization relies on strong acids or lewis acids as initiators. this distinction in reaction conditions can influence the choice of monomers and the overall efficiency of the polymerization process. lastly, the sensitivity of anionic polymerization

water soluble polymer flocculants synthesis,flocculants with less than 1% charged functional groups are considered as nonionic flocculants. 34 nonionic flocculants normally have high molecular weights, which helps them flocculate suspended particles through the bridging mechanism. 35 polyacrylamide is the most important water soluble nonionic flocculant because its monomer, acrylamide

polyacrylamide production market in kenya

polyacrylamide (pam) is a kind of linear water-soluble polymer, which is the most commonly used water treatment agent in our sewage treatment! in our practical application, pam can be divided into cationic, anionic and non-ionic three types. how to choose these three types of pam, we should start from the differences!