- Classification: chemical auxiliary agent

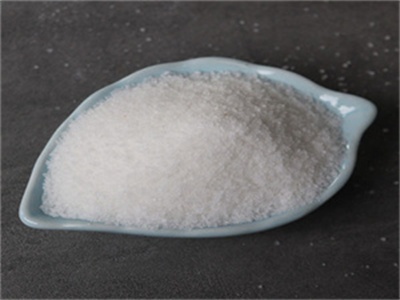

- Appearance: off-white granular powder

- CAS No.:9003-05-1085

- Type: cationic

- Formula: (C3h5no)N

- Solid Content: ≥91%

- Application:oil well drilling waste water treatment polyacrylamide

- Transport Package: 25kg/bag, 1000kg/bag, customized package

- Delivery: 3-5day

flocculants in wastewater treatment polyacrylamide

flocculants are substances that promote the agglomeration of fine particles present in a solution, creating a floc, which then floats to the surface (flotation) or settles to the bottom (sedimentation). this can then be more easily removed from the liquid. flocculants can be organic or inorganic, and come in various charges, charge densities

10 water treatment companies in lagos, nigeria environment go!,gratiam suam water resources which is one of the water treatment companies in lagos, nigeria is located at 3-9, olu koleosho street, off medical road, ikeja. visit site here. 5. still water multi drilling company. still waters multi drilling is one of the water treatment companies in lagos, nigeria.

application of flocculants in wastewater treatment

abstract. flocculation is an essential phenomenon in industrial wastewater treatment. inorganic coagulants (salts of multivalent metals) are being commonly used due to its low cost and ease of use. however, their application is constrained with low flocculating efficiency and the presence of residue metal concentration in the treated water.

recent advancement of coagulation–flocculation and its,increasing environmental awareness coupled with more stringent regulation standards has triggered various industries to challenge themselves in seeking appropriate wastewater treatment technologies. coagulation–flocculation process is regarded as one of the most important and widely used treatment processes of industrial wastewaters due to its simplicity and effectiveness. this paper

recent advances on coagulation-based treatment of wastewater

the coagulation-flocculation process is a prevalent method in water and wastewater treatment due to its effectiveness in removing organic matter, suspended solids, turbidity, and color [4, 5]. the conventional coagulation process involved the addition of divalent positively charged chemical compounds such as aluminum sulfate and ferric chloride

chemicals polyacrylamide manufacturers latest price,find here polyacrylamide, 9003-05-8 manufacturers, suppliers exporters in india. get contact details address of companies manufacturing and supplying polyacrylamide, 9003-05-8 across india.

bioflocculants for wastewater treatment: scale up flocculant

15.2. selection of bioflocculants. flocculation plays an essential choice in wastewater treatment among various traditionally adopted methods ( shih et al., 2001 ). the process of flocculation is dependent on the naturalization of charge, entrapment of colloid, and bridging ( teh et al., 2016 ).

cpam linear cas 9003-05-8 cationic polyacrylamide powder.high quality cpam linear cas 9003-05-8 cationic polyacrylamide powder from china, china’s leading cpam cationic polyacrylamide powder product, with strict quality control cas 9003-05-8 factories, producing high quality oilfield cationic polyacrylamide powder products.

wastewater management in lagos, nigeria rp facilities

addressing the wastewater crisis in lagos to effectively tackle the wastewater crisis in lagos, a multi-pronged approach is required, including: 1. expansion and modernization of the sewage network and treatment facilities. 2. enforcement of environmental regulations and proper disposal practices. 3.

waste water treatment philippines flocculant polyacrylamide,company was esteblish in 2002 and specialized in the production of polyaluminium chloride(pac), polyacrylamide(pam) and other water treatment chemicals.our products are widely metallurgy, paer mills, coal washing, textile, printing and dyeing, petroleum, chemicals and urban water supply and drainage and

coagulation and flocculation in water treatment explained

the main purpose of coagulation and flocculation is to treat turbid (hazy or cloudy) water, thus improving water quality. this is especially key for wastewater treatment, and can reduce organic loads and suspended solids by up to 90%. suspended solids are commonly found in the majority of surface water supplies and all wastewater supplies.

anionic polyacrylamide pam in dubai anionic polyacrylamide,industrial waste water treatment 1. sludge thickening 2. dewatering 3. colour removal 4. metallurgy 5. sewage treatment for various industries such as paper making 6. mining 7. coal mining 8. petroleum u ses of polyacrylamide (pam) waste water clarifications including primary, secondary and sludge thickening dewatering applications

pam water treatment, water soluble polymers, polyacrylamide pam

high quality nonion polyacrylamide pam npam nonionic surfactant for waste water treatment from china, china’s leading pam water treatment product, with strict quality control water soluble polymers factories, producing high quality water soluble polymers products.

china polyacrylamide polymers (pam) cas no. 9003-05-8,product details. 1. product introduction. polyacrylamide polymers (pam) cas no. 9003-05-8 . molecular formula: (c3h5no)n. h.s. code: .00. polyacrylamide polymers (pam) is a water-soluble high polymer and widely used in petroleum, paper-making, metallurgical, textile, chemical and environment protection fields.

chemical polyacrylamide 9003-05-8 chemical supplier

visit chemical supplier to find more polyacrylamide(9003-05-8) information like chemical properties,structure,melting point,boiling point,density,molecular formula,molecular weight, physical properties,toxicity information,customs codes. you can also browse global suppliers,vendor,prices,price,manufacturers of polyacrylamide(9003-05-8). at last,polyacrylamide(9003-05-8) safety, risk, hazard and

anionic polyacrylamide pam in malaysia anionic flocculant,industrial waste water treatment 1. sludge thickening 2. dewatering 3. colour removal 4. metallurgy 5. sewage treatment for various industries such as paper making 6. mining 7. coal mining 8. petroleum u ses of polyacrylamide (pam) waste water clarifications including primary, secondary and sludge thickening dewatering applications

insight into enhancing the performance of sludge dewatering

by contrast, organic flocculants, such as polyacrylamide (pam) and cationic polyacrylamide (cpam), possess unique advantages, such as low dosage requirement with wide ph range for application (feng et al. 2022, li et al. 2016). however, despite its popularity, the use of organic polymers has certain disadvantage relative to the secondary pollution.

high molecular nonionic polyacrylamide flocculating agent,high quality high molecular nonionic polyacrylamide flocculating agent npam powder from china, china’s leading poly aluminium chloride coagulant 25kg/ bag product, with strict quality control 215-477-2 poly aluminium chloride coagulant factories, producing high quality einecs no 215-477-2 pac coagulant products.

- How is an anionic polyacrylamide flocculant synthesized?

- In this study, an anionic polyacrylamide flocculant was synthesized by ultrasonic initiated template copolymerization (USTP), using sodium allylsulfonate (SAS) and acrylamide (AM) as monomers, poly diallyl dimethyl ammonium chloride (polyDADMAC) as template, and 2,2′-azobis [2- (2-imidazolin-2-yl) propane] dihydrochloride (VA-044) as initiator.

- Is Apam-t a novel anionic polyacrylamide?

- APAM-T is a novel anionic polyacrylamide which has been successfully synthesized by ultrasonic initiated template copolymerization. Characterization results showed the evidence of the microblock structure’s existence and the enhancement of copolymerization degree by adding the template.

- Can polymer flocculants destabilize particles?

- There are a couple of steps before one can successfully use polymer flocculants to destabilize particles in each media. Changing flocculant dose, molecular weight (MW), charge density, synthesis of new polymer, or employing a mix of flocculants/coagulants for maximum efficiency are just a few examples.

- Is cationic Pam effective in flocculation?

- The success of anionic and cationic PAM in flocculation can be related to particle charges that allow for particle flocculation with polymers. Non-ionic PAM was shown to be ineffective at flocculating tailing particles. The ionicity of the polymer appears to be highly relevant here, based on the results.