- Classification: chemical auxiliary agent

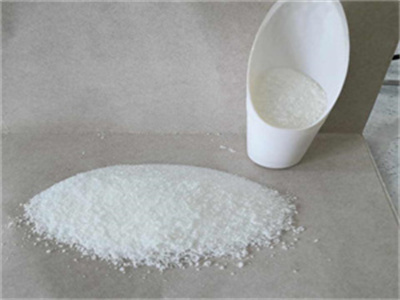

- Appearance: white fine-sand shaped powder or granule

- CAS No.:9003-05-1245

- Type: anionic

- Formula: (C3h5no)N

- Solid Content: ≥88.9%

- Application:drinking water treatment

- Transport Package: one 20’fcl load in 15-18mt palletized

- Delivery: 3-5day

anionic polyacrylamide (pam) application

the pam will—. be free of nonylphenol (np) and nonylphenol ethoxylates (npe), often used as surfactants. be of the anionic type meeting acrylamide monomer limits of ± 0.05 percent. have a charge density of 10 to 55 percent, by weight. have a molecular weight of 6 to 24 mg/mole.

anionic polyacrylamide cationic anionic polyacrylamide,high polymer water treatment anionic polyacrylamide,anionic polyacrylamide is the copolymer of acryl. mide and acrylic acid. no studies on the environmental fate of polyac. ylamide are available. as a high-molecular weight, water-soluble polymer, it is not expected to biode. rade or bioaccumulate. anionic polyacrylamide has a low acute toxicity concer.

pam (anionic polyacrylamide) industrial chemical products

pam (anionic polyacrylamide) for runoff and soil erosion control. pam, or anionic polyacrylamide, is a very long chain, high molecular weight organic polymer produced from natural gas, with characteristics which make it useful as a soil amendment to control runoff and soil loss. the chemical when applied as a liquid solution to a freshly-tilled

anionic polyacrylamide (pam) application (ac.) (450,download the national anionic polyacrylamide (pam) application (ac.) (450) conservation practice standard and supporting documents. national standard document notice national conservation practice standards should not be used to plan, design or install a conservation practice.

technical guidance for the use of polyacrylamide (pam) flocculant

applied polymer systems, inc / nov. 2002 / agency / pam tech. guide / info sheet pam application- criteria for land applied pam specifications pam shall be mixed and/or applied in accordance with all occupational safety and health administration (osha) polyacrylamide polymer material safety data sheet (msds) requirements and the manufacturer’s recommendations for the

polyacrylamide (pam) prices wholesale flocculant,polyacrylamide (pam) is a water-soluble polymer, physically available as a white crystalline solid. it is a non-ionic compound which forms strong hydrogen bonds with water molecules and hence capable to retain water. this water absorbing and retention quality makes it suitable to be used as a super absorbent.

polyacrylamide high purity pam powder

dewatered polyacrylamide emulsions differs from standard by the fact that they contain less than 6% water, with the result that the hydrogel has become almost the dry polymer itself. the consistency of the polymer is similar to plastic material. most dewatered polyacrylamide emulsions from polyacrylamide manufacturer have names starting by dw.

cationic polyacrylamide copolymers (pam): environmental half.background cationic polyacrylamide copolymers (pam) are used for sludge dewatering in municipal waste water treatment and might enter the environment by spreading of the sludge on agricultural land. concern has been expressed since little is known about the degradation of pam in soils. to obtain detailed information on the polymer’s fate in the soil compartment, the degradation of 14c

best practices guidance for the use of anionic polyacrylamide

pam aids solid-liquid separation by causing suspended particles to bind and form larger aggregates. the process is known as polymer bridging. one of the most common polymer flocculants on the market. common uses of pam as a flocculant: reduction of sediment and nutrient loads to natural lakes and ponds.

characterization and coagulation-flocculation performance of sale,characterization and coagulation-flocculation performance of a composite flocculant in high-turbidity drinking water treatment chemosphere . 2018 sep:206:701-708. doi: 10.1016/j.chemosphere.2018.04.159.

degradation of polyacrylamide and its significance in nature

the hydrolyzed form of polyacrylamide (hpam), a co-polymer of acrylamide and acrylic acid, is the most widely used anionic pam in oil and gas development as well as in soil conditioning.

methylated mud snail protein as a bio-flocculant for high,the authors reported a potential candidate methylated mud snail protein (memsp) as an effective and eco-friendly flocculant to treat the high turbidity wastewater. memsp was obtained by extraction of mud snail protein (msp) through isoelectric precipitation (psc-ip) and then methylated via the esterification with side-chain carboxyl.

unraveling the potential of microbial flocculants

microbial flocculants (mbfs), a class of eco-friendly and biodegradable biopolymers produced by various microorganisms, have gained increasing attention as promising alternatives to conventional chemical flocculants in wastewater treatment and pollutant removal. this review presents a comprehensive overview of the current state of mbf research, encompassing their diverse sources (bacteria

degradation of polyacrylamide and its significance in nature,chemical degradation of pam that leads to chain scission involves activation of the polymer by free radicals, 42,62,63,64,65,66 most commonly hydroxyl radicals generated in the environment from

a comprehensive review of polyacrylamide polymer gels for sale

they include polymer flooding, alkaline-surfactant flooding, foam flooding, gel treatments, and so on. among these methods, polyacrylamide polymer gel treatment is a common and cost-effective method because the process can reduce water cut by sealing the thief zone and redistributing the water drive.

evaluation an anionic polyacrylamide flocculant with low cost,the wastewater used in the flocculation test was simulated hematite wastewater (ph 6.5, high turbidity) which contained 2 g hematite power per 1000 ml distilled water. after the flocculant was added, the apparatus ran as this program: 200 r/min fast stirring for 3 min, 30 r/min slow stirring for 12 min.

fabrication of a cationic polysaccharide for high performance

the flocculant was used to treat kaolin suspension and actual wastewater. effects of initial ph, cdcs dosage, and temperature on flocculation properties were studied. the flocculation performance of cdcs was compared with those of commercial flocculants, polyacrylamide (pam) and ferric sulfate (fs). 2. materials and methods2.1. materials

cas 9003-05-8 cationic polyacrylamide cpam chemicals raw,high quality cas 9003-05-8 cationic polyacrylamide cpam chemicals raw materials from china, china’s leading organic flocculating agents cpam chemicals product, with strict quality control cas 9003-05-8 cpam chemicals raw materials factories, producing high quality cas 9003-05-8 cpam chemicals raw materials products.

- How can flocculating agents improve the stability of flocculated suspensions?

- Use of Flocculating Agents: Introducing flocculating agents during the formulation can enhance the stability of flocculated suspensions by promoting the formation of larger, more easily dispersible flocs. 1.

- What is a flocculated suspension?

- Definition: In flocculated suspensions, particles are loosely aggregated, forming flocs or clusters. These clusters are held together by weak physical forces such as van der Waals forces or electrostatic interactions. Relatively rapid settling of particles. Easy redispersion with mild agitation or shaking.

- How can I improve the stability of a flocculated suspension?

- 1. Redispersion: Gentle agitation or stirring before use can help redisperse the flocs and maintain a more uniform suspension. 2. Use of Flocculating Agents: Introducing flocculating agents during the formulation can enhance the stability of flocculated suspensions by promoting the formation of larger, more easily dispersible flocs.

- Can ionic surfactants be used as flocculating agents?

- Surfactants: Both ionic and nonionic surfactants can be used as flocculating agents. Ionic surfactants cause flocculation by neutralizing the charge on particles. Because of long structure, nonionic surfactants are adsorbed onto more than one particle, thereby, forming a loose flocculated structure.