- Classification: chemical auxiliary agent

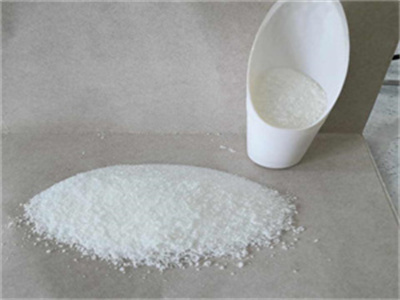

- Appearance: white particles

- CAS No.:9003-05-1498

- Type: nonionic

- Formula: (C3h5no)N

- Solid Content: ≥87.9%

- Application:waste water treatment in pharmaceutical

- Transport Package: 25kg / bag, kraft paper bag or as requested

- Delivery: 5-15days after deposit

spmc technical review

the evaluation results of each additive, including aluminum sulfate, the conventional pam as a dry strength additive, and cationic polymer as a coagulant, are compared to those of pm7460. the ionization degree represents the amount of anionic substances present in the filtrate from the pulp slurry. the turbidity

dry strength additives polyacrylamide powder,dry strength additives. dry strength is a key quality parameter for all paper and board grades. kemira’s broad portfolio of dry strength additives include specifically designed technologies to be used with virgin, mechanical, recycled or mixed fibers and for the production of various paper, board, and tissue grades as well as molded fiber.

anionic acrylamide co-polymer as dry strength additive for paper

dry strength additives are hydrophilic polymers, which enhance the effective bonding area, surface energy or hydrogen bonding ability. a resin, which is used to improve dry strength of paper, is called dry strength additive and must fulfill following requirements. it should improve dry strength by at least 15% over the normal dry strength of paper.

anionic polyacrylamide flocculant wastewater treatment agent,excellent effect under high-electrical conductivity conndition. ds4431: amphoteric: 20: 4000~: 2.5~4.5: excellent effect of enhancing drainage and retention. improve retention of sizing agents and dyes. ds4424: amphoteric: 20: 4000~: 2.5~4.5: excellent effect of enhancing the paper strength and retention under the condition

best practices guidance for the use of anionic polyacrylamide

pam aids solid-liquid separation by causing suspended particles to bind and form larger aggregates. the process is known as polymer bridging. one of the most common polymer flocculants on the market. common uses of pam as a flocculant: reduction of sediment and nutrient loads to natural lakes and ponds.

ethiopia exporter polyacrylamide pam high purity polyacrylamide,classification: chemical auxiliary agent: appearance: white granule/power: molecular weight: 28-30 million: cas no. 9003-05-8: package: one 20’fcl load in 18-20mt for usual

hercobond plus dry strength additives packaging solenis

5 to 15% increase in reel speed. 4 to 8% reduction in basis weight. 10 to 30% increase in compression strength or tensile strength at equal basis weight. $2 to $4 return on investment for every $1 of hercobond plus spent. the following case history details additional real-world results: packaging mill improves productivity and product quality

polyacrylamide pam flocculant for water treatment with best quality.cas no.: 9003-05-8 hs code: appearance: white powder ionic type: anionic, cationic, nonionic package: net 25kg / Chemicals Polyacrylamide with inner plastic bag description: according to ionic characteristics, it can be divided into four types, non-ionic polyacrylamide npam, anionic polyacrylamide apam, cationic polyacrylamide cpam and amphoteric polyacrylamide.

advances in papermaking wet end chemistry application

polyacrylamide can be used alone or together with inorganic coagulants to make flocs bigger and more resistant to shear forces. cationic glyoxalated polyacrylamide (gpam) 11-2-2 cationic glyoxalated polyacrylamide (gpam) 11-2-3 anionic dry strength additives 11-2-4 cationic pam and amphoteric pam dry strength resins

water treatment polyacrylamide polymer science wiley online library,polyacrylamide (pam) and its derivatives are the most commonly used polymers in the preparation of polymeric gels for water control in petroleum reservoirs. this study involved the use of polyethylenimine (pei) as a crosslinker for pam. in this study, we investigated pam alkaline hydrolysis at high temperatures.

harima develops world’s first high molecular weight

“harmide t2” is the world’s first high molecular weight, amphoteric polyacrylamide (pam)-based paper strengthening agent to be certified by all 3 regulatory bodies as an indirect food additive. pam-based paper strengthening agents improve the dry strength of paperboard (in such products as cardboard boxes), polyacrylamide for printing paper and food

study on alkaline hydrolysis of polyacrylamide 13 nature,alkaline hydrolysis of polyacrylamide the following operating conditions: 45° pulse, acquisition time, 0.68 s; pulse delay 2.5 accumulation, more than 7,000 times; com

dm250 water well drilling rig geoprobe

drill mast specifications drill mast specifications head travel (in) 264: head travel (mm) 6706 head travel (ft) 22: head travel (m) 6.71 head crowd force (lbs) 6,700: head crowd force (kn) 30 head pull force (lbs) 12,000: head pull force (kn) 53 head side shift (in) 12: head side shift (mm) 305 prime mover hydraulic specs prime mover

borehole drilling in kenya 2024: costs, requirements, and more,how borehole drilling costs are determined: 1. by drilling method: air drilling / pneumatic percussion drilling: this under-balanced drilling technique uses compressed air or nitrogen to cool the drilling bit and remove well-bore cuttings instead of fluids. it’s best suited for stable grounds with proper rock formations.

iran exporter cation polyacrylamide pam with high quality

anionic polyacrylamide has a big range of high molecular weight from 05-25 million, with an anionic charge density ranging from 10-60%. it has medium molecular weight, and medium charge degree. it is most often used to increase the viscosity of water (creating a thicker solution) or to encourage flocculation of particles present in water.

flocculating agent chemicals polyacrylamide sciencedirect topics,polyacrylamide is widely used in municipal sewage, industrial wastewater treatment, and drinking water treatment in rivers and lakes. The adsorption and decolorization properties of polyacrylamide are often used in the papermaking, printing and dyeing, textile and leather production industries.

polyacrylamide thomas scientific

polyacrylamide 250 g. packaging size 250 g. polyacrylamide is a high polymerization, high molecular and water soluble polymer; it can be used in the petroleum, mineral separation, coal washing, metallurgy, chemical industry, paper-making, textile, sugar making, medicine, environment protection, building material and agriculture.) $0.00. thomas no. c759u02. mfr. no. p2930-500gm. description

polyacrylamide in delhi india business directory,filtron envirotech (india) is the leading manufacturer, exporter supplier of oil drilling chemicals, specialty polyacrylamide lcm. we are into manufacturing of polyacrylamide lcm delhi based and stands for assurance of quality of all products manufactured at our manufacturing facility.

- What is partially hydrolyzed polyacrylamide (PHPA)?

- Partially hydrolyzed polyacrylamide (PHPA), consisting of neutral acrylamide and anionic acrylate groups, is suitable for use in water with 25,000 mg/L TDS 12, 15.

- How much energy does hydrolyzed polyacrylamide produce?

- Practical energy used in the production of hydrolyzed polyacrylamide (HPAM) polymers is estimated to be around 123.6 MJ/kg. For gas, oil, and coal, this results in CO emissions of 3.25, 4.72, and 6.35 kg CO per kilogram of polymer, respectively.

- Which polymer is used to produce partially hydrolyzed polyacrylamide (HPAM)?

- PAM is used to produce partially hydrolyzed polyacrylamide (HPAM), which is linear, anionic, water-soluble, stable, polymeric, and high molecular weight chain of acrylamide (C 3 H 5 NO) monomers (Bao et al., 2010; Braun et al., 2022; Liu et al., 2016; Xiong et al., 2018 ).

- What is hydrophilic polyacrylamide (HPAM)?

- 5.1.1. Hydrolyzed Polyacrylamide (HPAM) The commercially used hydrophilic PAM used for cEOR is a copolymer of acrylamide (AM) and acrylic acid or variant of salts and is called HPAM. HPAM is highly hydrophilic, forming hydrogen bonds easily, and dissolves in water readily, creating a powerful tackifying (i.e., viscosifying) effect [ 97 ].