- Classification: chemical auxiliary agent

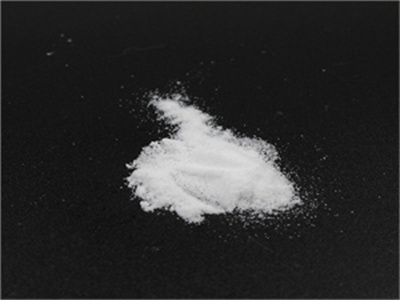

- Appearance: white/light yellow granule or powder

- CAS No.:9003-05-1796

- Type: cationic

- Formula: (C3h5no)N

- Solid Content: 89% Min

- Application:chemical industry

- Transport Package: 25kg kraft paper or customization

- Delivery: 15day

how to optimize polymer efficiency for better sludge dewatering

fairfield-suisun sewer district, ca. solano county, ca, 40 miles north san francisco. design capacity: 24 mgd tertiary treatment/ uv. population served: 135,000. polymer use for dewatering (screw press) and thickening (gbt) problems with existing polymer system. struggled to make proper polymer solution.

synthetic polymeric flocculants aid dewatering water technology,synthetic polymeric flocculants aid dewatering. march 1, 2000. most flocculants in use today are synthetic water soluble polymers based on acrylamide and its derivatives and which may include either anionic or cationic groups in a wide range of molecular weights and charge densities. they are supplied as dry powders or in liquid form as liquid

cationic polyacrylamide copolymers (pam): environmental half

background cationic polyacrylamide copolymers (pam) are used for sludge dewatering in municipal waste water treatment and might enter the environment by spreading of the sludge on agricultural land. concern has been expressed since little is known about the degradation of pam in soils. to obtain detailed information on the polymer’s fate in the soil compartment, the degradation of 14c

understanding polymer for thickening and dewatering processes,polymers can have different charges, charge densities, and molecular weights. polymers that have a positive charge (otherwise known as cationic) and a high molecular weight are typically used for thickening and dewatering solids separationprocesses. figure 3. a depiction of a floc formed by a cationic polymer chain bridging the solids particles.

novel methodologies for determining a suitable polymer for sale

since cationic polymers with high and very high molecular weight are widely used for conditioning and dewatering of wastewater sludge, especially for facility using centrifuges [26], the selection of appropriate polymers for conditioning generally focuses on the charge density and configuration of polymers. according to the y–intercept

basf expands production of polyacrylamide powder in nanjing,during the first quarter of 2019, basf has successfully ramped up commercial production of its new production line for polyacrylamide powder at its wholly-owned site in nanjing, china. the additional 20,000 metric tons per year capacity of polyacrylamide will support mining customers in asia pacific.

optimizing polymer mixing/activation improves sludge

ionic strength (hardness): multi-valent ion hinders polymer activation soft water helps polymer molecules fully-extend faster hardness over 400 ppm may need softener oxidizer (chlorine): chlorine attacks/breaks polymer chains should be less than 3 ppm caution in using recycled water for polymer mixing + serious negative impact on aging

cationic polymer powder with factory supply.water treatment raw materials factory price 9003-05-8 cationic polymer flocculant cationic polyacrylamide pam powder $ 1 .30 $ 1 .80 min order: 1000 kilograms

cationic polyacrylamide synthesis and application in sludge

polyacrylamide, a water-soluble polymer formed by the polymerization of acrylamide monomers, is among the most used chemicals for wastewater treatment and sludge dewatering. cationic

polyacrylamide pam flocculant for water treatment with best quality,cas no.: 9003-05-8 hs code: appearance: white powder ionic type: anionic, cationic, nonionic package: net 25kg / Chemicals Polyacrylamide with inner plastic bag description: according to ionic characteristics, it can be divided into four types, non-ionic polyacrylamide npam, anionic polyacrylamide apam, cationic polyacrylamide cpam and amphoteric polyacrylamide.

water soluble polymer flocculants synthesis

polymer adsorption can occur through hydrogen bonding (polyacrylamide on silica silanol groups), electrostatic interaction (cationic polymers on negatively charged sludge), hydrophobic interaction (poly(vinyl alcohol) on silver iodide), and ion bridging (anionic polyacrylamide on negatively charged clays with the help of divalent calcium ion). 7

cpam linear cas 9003-05-8 cationic polyacrylamide powder,high quality cpam linear cas 9003-05-8 cationic polyacrylamide powder from china, china’s leading cpam cationic polyacrylamide powder product, with strict quality control cas 9003-05-8 factories, producing high quality oilfield cationic polyacrylamide powder products.

anionic poly electrolyte powder manufacturer supplier in india

acuro’s is one of the best manufacturer supplier of anionic poly electrolyte, anionic polyelectrolyte powder, polyacrylamide,It is widely used in papermaking, mining, coal washing, metallurgy, oil exploitation and other industrial sectors and is also a important chemical for water treatment.

polyelectrolyte anionic polyelectrolyte powder manufacturer,anionic polyelectrolyte powder vedicorgo llp bring to you a range of polyelectrolytes for treatment of water from various processes. we offers top quality products, services and solution to all water related needs of various industries.

botswana factory hot offer cation polyacrylamide pam

detailed images factory price pam polyacrylamide liquid polyacrylamide liquid (pam) is a kind of linear organic high polymer, is also a kind of high polymer flocculant in water treatment products, can absorb the suspended particles in the water, link bridge role between the particles, the fine grain to form bigger floccules, and increasing the

polyelectrolyte in kenya, polyelectrolytes, polydadmac,polyelectrolyte we are the direct importers for anionic polyelectrolyte and cationic polyelectrolyte. 1. anionic polyelectrolyte 2. cationic polyelectrolyte 3. non ionic polyelectrolyte 4. anionic polyelectrolyte liquid 5. cationic polyelectrolyte liquid 6. polydadmac

polyacrylamide manufacturer supplier for waste water treatment

our company is located in zhengzhou city, henan province, china. we are a company specializing in the production of various chemical products. including polyacrylamide, anionic polymer, cationic polymer, nonionic polymer,pam, flocculant etc. suneco chem offers a very high degree of superior customization for its polyacrylamide.

india polyacrylamide copolymer market is projected to be,in the last few decades, polyacrylamide copolymer market has grown rapidly, market for polyacrylamide copolymer is anticipated to increase due to increase in demand for purified drinking water, the market is segmented on basis of type, application and geography polyacrylamide copolymer industry news and updates

- Can cationic polyacrylamide be used in water treatment and sludge dewatering?

- To read the full-text of this research, you can request a copy directly from the authors. Cationic polyacrylamide (CPAM) were used extensively in water treatment, enhanced oil recovery and sludge dewatering. The review summarized the synthesis methods research progress of cationic flocculants.

- Can cationic-surfactant polyacrylamide be used as a viscosifier in drilling fluid?

- Likewise, Shettigar et al. (2018) designed a cationic-surfactant polyacrylamide as viscosifier in drilling fluid, which showed the improvement of rheology and cutting effect due to the hydrophobic and electrostatic interaction between the surfactant (cetyltrimethyl ammonium bromide) and polymer.

- Can cationic polymers be used as primary coagulants in South Africa?

- The substitution of traditional hydrolysing reagents by cationic polymers (CPE) is becoming increasingly popular in South Africa, although no comprehensive investigation into the suitability of CPE as primary coagulants and their possible side-effects has been carried out.

- Can cationic polyacrylamide flocculants be used to treat oily water?

- Shu, G., Bu, K., Zhao, B. Zheng, S. Evaluation of newly developed reverse demulsifiers and cationic polyacrylamide flocculants for efficient treatment of oily produced water. Colloids Surf. A 610, 125646 (2021). This work was supported by grants from the “Qihang Program” of the Southwest Petroleum University (2023QHZ001) awarded to C.Z.