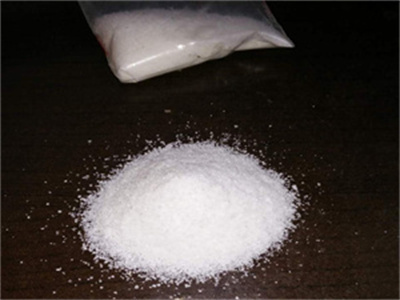

- Classification: chemical auxiliary agent

- Appearance: white crystal

- CAS No.:9003-05-1127

- Type: anionic,nonionic

- Formula: (C3h5no)N

- Solid Content: ≥92%

- Application:chemical,papermaking industries

- Transport Package: 25kg/bag, 1000kg/bag, customized package

- Delivery: 3-7day

neurotoxicity of acrylamide in exposed workers pmc

abstract. acrylamide (acr) is a water-soluble chemical used in different industrial and laboratory processes. acr monomer is neurotoxic in humans and laboratory animals. subchronic exposure to this chemical causes neuropathies, hands and feet numbness, gait abnormalities, muscle weakness, ataxia, skin and in some cases, cerebellar alterations.

acrylamide: a neurotoxin and a hazardous waste intechopen,acrylamide is an organic water-soluble compound and a vinyl-substituted primary amide. it is well known for its toxic effects on humans. this chemical may lead to neurodegenerative disorders like alzheimer’s and parkinson’s. it is exposed to humans through diet, occupation, lifestyle and many environmental factors. acrylamide is used in molecular laboratories and even in various

acrylamide neurotoxicity as a possible factor responsible for sale

similarly, the effect of acrylamide on acetylcholinesterase has been noted in studies with electric eel. it concerned the capture of acetylcholinesterase from electric eel in a polyacrylamide gel. the activity of the trapped enzyme was significantly reduced; the effect was due to acrylamide inhibition .

frontiers the mechanism of acrylamide-induced neurotoxicity,foodborne exposure. consumers can be directly exposed to acr via the oral intake of high-carbohydrate foods, such as potato chips, baked cereals, and bread ().as early as 2010, the jecfa presented data regarding the acr detected in 12,582 food samples from 31 countries, which included fried potatoes, bread, biscuits, coffee, and other food products.

the mechanism of acrylamide-induced neurotoxicity

acrylamide (acr), a potential neurotoxin, is produced by the maillard reaction between reducing sugars and free amino acids during food processing. over the past decade, the neurotoxicity of acr

best practices guidance for the use of anionic polyacrylamide,step water is a partnership between: best practices guidance for the use of anionic polyacrylamide on construction sites in ontario presented by: lisa rocha what we’ll cover •polymer basics (nature, safety, efficacy) •polymer literature review •field evaluation of anionic polyacrylamide (pam) ditch application tank application results

acrylamide and polyacrylamide a review of production, use

studies have shown that polyacrylamide is harmless to the body, but the acrylamide monomer released from polyacrylamide contains toxins [17]. the toxicity of acrylamide mainly includes

water treatment flocculation which flocculation agent is best?.it is important to strike a balance between high flocculation efficiency and the cost of handling the flocculant. increased efficiency can also bring cost savings, but it may be difficult for facility managers to accurately quantify the savings made. reducing the cost of sourcing the flocculation agent, on the other hand, is easy to quantify.

chemical polyacrylamide water treatment polymer

polyacrylamide (abbreviated as pam or paam) is a polymer with the formula (-ch 2 chconh 2 -). it has a linear-chain structure. pam is highly water-absorbent, forming a soft gel when hydrated. in 2008, an estimated 750,000,000 kg were produced, mainly for water treatment and the paper and mineral industries.

high quality cation polyacrylamide pam ethiopia with high quality,our eternal pursuits are the attitude of regard the market, regard the custom, regard the science and the theory of quality the basic, trust the first and management the advanced for pam chemical, cationic polyacrylamide for industrial, poly electrolyte, flocculant agitation tank, adhering to the business philosophy of’customer first, forge ahead’, we sincerely welcome clients from at

running agarose and polyacrylamide gels idt

agarose gels can be run at a large range of voltages—from 0.25–7 v/cm. high voltages save time but can result in overheating of the gel, even leading to melting of low percentage agarose gels. high voltages can also cause band smearing, particularly of fragments 10 kb.

high efficiency wastewater treatment agent polyacrylamide pam,high efficiency wastewater treatment agent polyacrylamide pam for sand washing coal washing plant , find complete details about high efficiency wastewater treatment agent polyacrylamide pam for sand washing coal washing plant,pam,polyacrylamide,water treatment agent from leather auxiliary agents supplier or manufacturer-henan mingyi environmental protection technology co., ltd.

high efficient anionic polyacrylamide flocculant polymer for sale

high quality high efficient anionic polyacrylamide flocculant polymer for sand washing water treatment from china, china’s leading cationic polyelectrolyte flocculants product, with strict quality control anionic pam factories, producing high quality sand washing polyacrylamide flocculant products.

best efficiency polyacrylamide water treatment agents pam,polyacrylamide(pam) water treatment agent. pam applications: anionic pam: it is widely used in waste water treatment of chemical industry, municipal sewage treatment, such as coal washing, mineral processing, metallurgy, iron and steel industry and electronic industry.it is also used in oil industry to enhance oil recovery which is widely used.

biopolymer-based flocculants a review of recent technologies

biopolymer-based flocculants have become a potential substitute for inorganic coagulants and synthetic organic flocculants due to their wide natural reserves, environmental friendliness, easy natural degradation, and high material safety. in recent years, with more and more attention to clean technologies, a lot of researches on the modification and application of biopolymer-based flocculants

25kg/bag coal washing polyacrylamide china pam flocculant,benefit from advanced technologies, first-class facilities, professional laboratory and strict quality management system, our product quality and supply ability are widely accepted by most high-end customers in our domestic. meanwhile, we achieve big success in overseas market, like in usa, southeast asia and south america ect.

cationic polyacrylamide: synthesis and application in sludge

high quality cationic polyacrylamide: synthesis and application in sludge dewatering treatment,cationic polyacrylamide: synthesis and application in sludge dewatering treatment: a review.polyacrylamide is widely used in printing and dyeing, paper industry, mining plant, coal preparation, oil field, metallurgical industry.

top 10 polyacrylamide manufacturers and suppliers in usa,looking for polyacrylamide manufacturers and suppliers in usa, here we listed top 10 polyacrylamide manufacturers and suppliers in usa. 1 usa water treatment manufacturers address: penthouse, 8730 wilshire blvd, beverly hills, ca,united states plus: 3j98+55 beverly hills, california, usa contact for a quick quote 2 oasis towels wholesale towel manufacturers usa […]

- What is SDS polyacrylamide gel electrophoresis (SDS-PAGE)?

- SDS polyacrylamide gel electrophoresis (SDS-PAGE) involves the separation of proteins based on their size. By heating the sample under denaturing and reducing conditions, proteins become unfolded and coated with SDS detergent molecules, acquiring a high net negative charge that is proportional to the length of the polypeptide chain.

- What acrylamide concentration is used for SDS-PAGE gel?

- The concentration of acrylamide used for the gel depends on the size of the proteins to be analyzed. Low acrylamide concentrations are used to separate high molecular weight proteins, while high acrylamide concentrations are used to separate proteins of low molecular weight (see table Compositions and separation properties of SDS-PAGE gels ).

- How are polyacrylamide gels characterized?

- Polyacrylamide gels are characterized by two parameters: total monomer concentration (%T, in g/100 ml) and weight percentage of crosslinker (%C). By varying these two parameters, the pore size of the gel can be optimized to yield the best separation and resolution for the proteins of interest.

- How do SDS-coated proteins migrate in a sieving polyacrylamide gel?

- In a sieving polyacrylamide gel, the rate at which the resulting SDS-coated proteins migrate in the gel is relative only to their size and not to their charge or shape Protein detection technology involving UV-induced haloalkane modification of protein tryptophan residues.