- Classification: chemical auxiliary agent

- Appearance: white granule/power

- CAS No.:9003-05-10387

- Type: cationic,nonionic

- Formula: (C3h5no)N

- Solid Content: ≥90.5%

- Application:sand prevention solidification industry

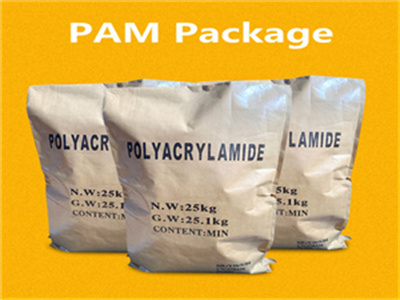

- Transport Package: one 20’fcl load in 15-18mt palletized

- Delivery: 3-7day

advanced treatment for actual hydrolyzed polyacrylamide-containing wastewater in a biofilm/activated sludge membrane bioreactor system

water treatment chemical flocculant nonionic anionic cationic polyacrylamide,advanced treatment for actual hydrolyzed polyacrylamide-containing wastewater in a biofilm/activated sludge membrane bioreactor system: biodegradation and interception @article{zhao2019advancedtf

water treatment flocculant polymer highchem trading,anionic polymer and cationic polymer are flocculants / flocculation chemicals used in waste water treatment processes for solids removal, water clarification, lime softening, sludge thickening, and solids dewatering. these are normally used in conjunction with a coagulant chemical, poly aluminum chloride.

how much do dental implants cost in 2024? forbes

levin estimates the total cost per tooth, start to finish, normally runs between $3,000 and $4,500, and a person who needs a mouthful of implants is looking at a final price of between $60,000 water treatment

chemical flocculant anoinic cantion polyacrylamide in singapore costs,aside from the costs involved, dental implant surgery and implant placement require sufficient bone in the jaw to support the implant. patients with uncontrolled diabetes, active gum disease or on strong blood thinners may not be suitable for implant surgery.

polyacrylamide for wastewater treatment

polyacrylamide is granule or white powder.it has a variety of active group, with many substances affinity adsorption, forming hydrogen bond. mainly flocculation negatively charged colloid in turbid, bleaching, adsorption, adhesive and so on the function, apply to imine tailing treatment, coal mine washing, wastewater treatment in dyeing, papermaking, foodstuff, building, metallurgy, coal, oil and mineral, aquatic products processing and fermentation etc,

a contemporary review on plant-based coagulants for good price,the m. oleifera working doses are within the typical range of alum that is used in a water treatment plant [91]. plants with active coagulant ingredients have a potential to be commercialised like current industrial crops. they offer wide range of active ingredients that can be harvested and used in a conventional water treatment plant.

treatment of polyacrylamide production wastewater treatment multistage contact reactor with activated and anammox sludge sciencedirect

after flocculation treatment, production wastewater was added into a 500 l influent storage tank and the ph was adjusted to 7.3 ± 0.5 using a 30% sulfuric acid solution. the main composition of the wastewater was (nh 4) 2 so 4, am, cationic pam, anionic pam, amphoteric pam, non-ionic pam of different molecular weights, sanitary wastewater in factory and some other organic matters (cod cr 1200

best selling oil well hydrophilic polyacrylamide 9003-05-8.fig,anionic polyacrylamide apam,polyacrylamide manufacturer polyacrylamide manufacturer,moq:1 ton,iso 9001, iso 14000, and sgs certificate。polyacrylamide/phpa, oil field chemicals。request quotes now! free sample requests。

polyacrylamide 9003-05-water treatment pam with best price

find here polyacrylamide, 9003-05-8 manufacturers, suppliers exporters in india. get contact details address of companies manufacturing and supplying polyacrylamide, 9003-05-8 across india.

ghana factory made anionic polyacrylamide anionic pam,best practices guidance for the use of anionic polyacrylamide. anionic pam use in ontario polymer products evaluated anionic pam based products manufactured by applied polymer systems (aps) primary product used was the floc log, a semi-solid block composed of drinking water chemicals and pam in the ditch application an anionic pam-based powder, sold by aps as silt stop, was

polymer cationic polyacrylamide msds chinafloc

chinafloc is a professional manufacturer and supplier of acrylamide, polyacrylamide and flocculant in qingdao, china. polymer cationic polyacrylamide msds chinafloc——top ten in china! exporting to 68 countries!

study on flocculation performance of new cationic polyacrylamide,compared with pam and cpam, this flocculant has a lower water content in the filter cake after treating wastewater, making the subsequent treatment easier. moreover, the flocculant is resistant to high temperature. specifically, at 40 °c, the filter cake moisture content (fcmc) is still lower than those of pam and cpam.

potential of fruit peels in becoming natural coagulant for good price

of fruits peels as natural coagulants in treating water over the use of alum. 2. methodology 2.1 materials water sample was collected from water treatment plant, taman impian emas, johor bahru. in terms of selection of natural coagulants, this study focused on the local waste materials specifically the fruit peels. the collected peels are

polyacrylamide for industry water treatment,the hydrolyzed form of polyacrylamide (hpam), a co-polymer of acrylamide and acrylic acid, is the most widely used anionic pam in oil and gas development as well as in soil conditioning.

anionic polyacrylamide factory price flocculant

no studies on the environmental fate of anionic polyacrylamide are available. as a high-molecular-weight, water-soluble polymer, it is not expected to biodegrade or bioaccumulate (lyons and vasconcellos, 1997). the environmental fate of anionic polyacrylamide will be determined primarily by adsorption (lyons and vasconcellos, 1997).

cationic polyacrylamide copolymers (pam): environmental half,background cationic polyacrylamide copolymers (pam) are used for sludge dewatering in municipal waste water treatment and might enter the environment by spreading of the sludge on agricultural land. concern has been expressed since little is known about the degradation of pams in soils. to obtain detailed information on the polymer’s fate in the soil compartment, the degradation of 14c

solved in chemical polyacrylamide gel electrophoresis pam

question: in chemical polyacrylamide gel electrophoresis, proteins are resolved based on their: shape overall charge tertiary structure mass quaternary structure put the following immunoblotting steps in the correct order: the proteins are transferred from the gel to the blot using electrophoresis.