- Classification: chemical auxiliary agent

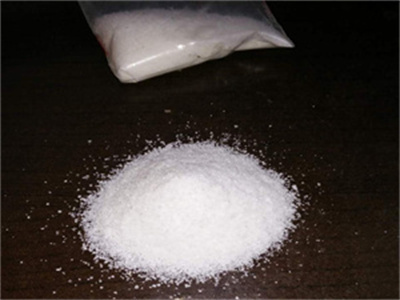

- Appearance: white crystal

- CAS No.:9003-05-1688

- Type: cationic

- Formula: (C3h5no)N

- Solid Content: 89% Min

- Application:water & air treatment,oilfield chemicals

- Transport Package: 25kg kraft paper bag

- Delivery: 5-15days after deposit

polyacrylamide high purity pam powder

Polyacrylamide (PAM) for Papermaking Wastewater Treatment can improve the retention rate of fillers and pigments, as well as paper strength when used as a reinforcing agent and other auxiliary materials in papermaking.

advances in papermaking wet end chemistry application,chapter 5 -paper machine white-water systems and the paper machine wet end 5-1 background and historical review 5-1-1 the invention of paper 5-1-2 early mechanized papermaking 5-1-3 parts of a typical paper machine 5-2 technological aspects of sheet forming 5-2-1 how the volume of stock in a paper machine system affects process control

chemical polyacrylamide (PAM) flocculant types

pam is the abbreviation of polyacrylamide, polyacrylamide is a water-soluble polymer, widely used in petroleum, paper making, metallurgy, textile, chemical industry and environmental protection. there are three major categories: anionic, cationic and non-ionic. different applications require different grades of polyacrylamide. view more

technical specification poly acrylamide water treatment,technical specification poly acrylamide product name: poly acrylamide cas no: 9003-05-8 formula: c3h5 no molecular weight: 71.0079 description: polyacrylamide, known as pam, is a white powder or granule. polyacrylamide is a kind of macromolecule polymer. it is not soluble in some organic solvents. provided with a good

polyacrylamide (pam) high performance polymers and their

this chapter contains sections titled: introduction and history polymerization and fabrication properties chemical stability compounding and special additives processing applications blends of polya.

acrylamide manufacturer, polyacrylamide supplier, flocculant,the polyacrylamide (pam) produced by hangrui is a water-soluble polymer, insoluble in most organic solvents, and has great flocculation result. it can reduce the frictional resistance between liquids. according to the ionic character, it can be divided into three types: anion, cation and non-ion.

polyacrylamide in paper industry: enhancing strength flocculant

this leads to improved efficiency in papermaking processes. controlling paper’s water retention:polyacrylamide can regulate the water retention of pulp during paper production. it aids in maintaining proper moisture levels in paper, ensuring better performance during printing, and processing. enhancing filler dispersion:dispersion of fillers is

super absorbent polymer anionic cationic nonionic.overview of super absorbent polymer anionic cationic nonionic polyacrylamide for sludge dewater flocculant. anionic surfactants are a class of surface-active agents characterized by a negatively charged hydrophilic head group when dissolved in water.

production, import/export, use, and disposal

they aid in dewatering sludge from sewage treatment plant effluent as well as industrial waste water from pulp and paper plants (abdelmagid 1982; haberman 2002). polyacrylamide are also found in cosmetics and toiletries and are used to prepare polyacrylamide gels for use in biotechnology laboratories (eu 2002; lewis 2007). in the oil industry

polyacrylamide market size share growth forecasts 2036,the polyacrylamide market size is expected to reach usd 12 billion by the end of 2036, growing at a cagr of 7% during the forecast period, i.e., 2024-2036. asia pacific industry is projected to hold the largest revenue share of 36% by 2036, due to increasing industrialization in the region.

polyacrylamide chemical economics handbook (ceh) s p global

call +1 800 752 8878. published january 2021. acrylamide is a water-soluble monomer, industrially produced by the hydration of acrylonitrile. the principal acrylamide derivatives are polyacrylamide (both homopolymers and copolymers) that have varying water solubility characteristics. these polymers are used widely in water treatment, petroleum

indonesia manufacturing industry: special chemicals,the data reached an all-time high of 753.788 idr bn in 2003 and a record low of 18.429 idr bn in 2004. indonesia manufacturing industry: special chemicals: polyacrylamide polymer (modified cationic) denture adhesive data remains active status in ceic and is reported by central bureau of statistics.

simple cationic polyacrylamide: a drag reducer iranian

a very simple cationic monomer and a cationic hydrophobically associating polyacrylamide were synthesized, and the polymer was to function as a drag reducer. the structures of monomer and polymer were characterized by ir and nmr, and the drag-reducing rate, below and above the critical association concentration, (cac) was tested. the modified polyacrylamide is a typical hydrophobically

optimizing the conditions of cationic polyacrylamide inverse,cationic polyacrylamide (cpam) is one of the most widely applied polymers due to its high performance in flocculation, sludge dewatering, and harvesting microalgae [6,7,8,9,10,11,12,13].

acrylamide manufacturer, polyacrylamide supplier, flocculant

acrylamide manufacturer, polyacrylamide supplier, super absorbent polymerpolyacrylamide products contact us chinafloc

global polyacrylamide market by form (liquid, solid), type,5.1. market dynamics 5.1.1. drivers 5.1.1.1. growing usage of polyacrylamide in water and wastewater treatment 5.1.1.2. increasing need for polyacrylamide in the oil and gas industry for enhanced oil recovery

one-pot production of a graft copolymer of cationic starch

abstract. a newly developed, high-performance, and environmentally friendly flocculant, i.e., a graft copolymer of cationic starch and cationic polyacrylamide (sc-cpam), is synthesized via a single-step pathway in which the cationic agent is incorporated onto the starch backbone and into the polyacrylamide grafted branch simultaneously.

drilling chemical pam anionic polyacrylamide for crude oil,usage: electronics chemicals, leather auxiliary agents, paper chemicals, petroleum additives, textile auxiliary agents, water treatment chemicals; model number: yg; product name: drilling chemical pam anionic polyacrylamide for crude oil petroleum; appearance: white power; sample: samples provided; cas number: 9003-05-8; solubility: easily soluble

- What is polyacrylamide (PAM) used for?

- High molecular weight polyacrylamide (PAM) is commonly used as a flocculant in water and wastewater treatment, a soil conditioner, and a viscosity improver and friction reducer in enhanced oil recovery and high-volume hydraulic fracturing.

- What is high molecular weight polyacrylamide (PAM)?

- Supplied by Our Company High molecular weight polyacrylamide (PAM) is commonly used as a flocculant in water and wastewater treatment, a soil conditioner, and a viscosity improver and friction reducer in enhanced oil recovery and high-volume hydraulic fracturing.

- Where is Pam used in water treatment sludge dewatering?

- PAM used as a flocculant in water treatment or sludge dewatering is disposed of in high-solids biogas digesters or landfills. 94 Although PAM is generally considered relatively refractory to organic decomposition,95 it can be degraded during anaerobic digestion.

- How is partially hydrolyzed polyacrylamide wastewater treated?

- Combined Fenton oxidation and anaerobic biological process for treatment of partially hydrolyzed polyacrylamide wastewater.