- Classification: chemical auxiliary agent

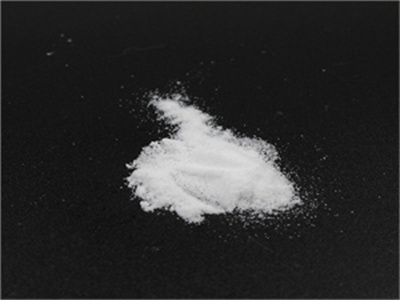

- Appearance: white/light yellow granule or powder

- CAS No.:9003-05-504

- Type: anionic,cationic

- Formula: (C3h5no)N

- Solid Content: ≥89.5%

- Application:chemical industry

- Transport Package: 25kg / bag, kraft paper bag or as requested

- Delivery: prompt shipment

polyacrylamide (pam), polyacrylamide powder, polyacrylamide

polyacrylamide (pam) is commonly used as a flocculant in water wastewater treatment, pulp and paper production, agriculture, food processing and mining. which is based on polyacrylamide copolymers providing the complete range of ionicities and molecular weights necessary to meet optimal performance for each applications.

polymer water treatment of flocculation,emulsion: 6 months, un-opened drum/tote. dry: up to 3 years, un-opened bag. polymer solution: depends of concentration, water quality. storage temperature: 40 f 90 f. do not allow emulsion to freeze. once frozen, thaw in heated area and mix well. handling. wear latex gloves and eye protection.

degradation of polyacrylamide and its significance in nature

the hydrolyzed form of polyacrylamide (hpam), a co-polymer of acrylamide and acrylic acid, is the most widely used anionic pam in oil and gas development as well as in soil conditioning.

recent achievements in polymer bio-based flocculants for sale,among the synthetic polymer flocculants, the most important is water-soluble polyacrylamide (pam)—a non-ionic, amorphous polymer which can be modified to ionic form in the copolymerization process. the acrylamide monomer can be used for grafting or crosslinking of other type of polymers.

water soluble polymer flocculants synthesis

flocculants with less than 1% charged functional groups are considered as nonionic flocculants. 34 nonionic flocculants normally have high molecular weights, which helps them flocculate suspended particles through the bridging mechanism. 35 polyacrylamide is the most important water soluble nonionic flocculant because its monomer, acrylamide

india polyacrylamide suppliers, manufacturers, wholesalers,find polyacrylamide suppliers. get latest factory price for polyacrylamide. request quotations and connect with india manufacturers and b2b suppliers of polyacrylamide.

anionic polyacrylamide cationic anionic polyacrylamide

molecular formula: (c3h5no)x- and (c3h3o2)x-. molecular weight: 1,000,000 to 50,000,000 g/mol for polyacrylamide copolymers used as flocculants (lyons and vasconcellos, 1997) synonyms: anionic polyacrylamide. co-chemical propertiespolyacrylamide polymers can exist in cationic, anionic or non-ionic forms, depending.

best selling customized polyacrylamide cpam water treatment polymer.polyacrylamide cpam water treatment polymer. product name: polyacrylamide cpam water treatment polymer cas no: 9003-05-8 hs code: appearance: white particles grade: fine chemical tnn specializes in food additives, pharmaceutical ingredients, cosmetic raw materials, fine chemicals, etc.

polyacrylamide pam flocculant for water treatment with best quality

polyacrylamide pam powder. cas no.: 9003-05-8. hs code: . appearance: white powder. ionic type: anionic, cationic, nonionic. package: net 25kg / Chemicals Polyacrylamide with inner plastic bag. description: according to ionic characteristics, it can be divided into four types, non-ionic polyacrylamide npam, anionic polyacrylamide apam, cationic

polyacrylamide market size, share growth report, 2030,polyacrylamide market size trends. the global polyacrylamide market size was estimated at usd 5.5 billion in 2022 and is projected to grow at a compound annual growth rate (cagr) of 6.5% from 2023 to 2030.

measuring poly(acrylamide) flocculants in fresh water using

anionic and cationic polymer variants of copolymers of acrylamide are used in the flocculation of waste effluent. 20 the polymers are added to wastewater to improve the settling and the subsequent removal of suspended particles, either by direct flocculation or by neutralising the suspended particles surface charge. 18,21 both polymers are

the efficiency of polyaluminum chloride and anionic,the coagulation and flocculation method stands out as a widely utilized approach in industrial wastewater treatment. this study explores the application of a new sedimentation concept, focusing on one-step removal, and evaluates the effectiveness of polyaluminum chloride (pac) and anionic polyacrylamide (pam) in reducing turbidity in simulated hot-rolled steel factory effluent. the

Water Treatment

Anionic Polyacrylamide chemicals

anionic polyacrylamide calcium hypochlorite cationic polyacrylamide chlorine lime ferric chloride solution 44% flocculants (polyelectrolytes) non anionic polyacrylamide polyaluminium chloride (pac) polydadmac powdered activated carbon 1,3- diamino urea (carbohydrazine) 2- bromo-2- nitropropane 1,3 diol (bnpd)

flocculant polyacrylamide in egypt high purity polyacrylamide,factory supply 1,836 best price of polyacrylamide products. about 31% of these are electronics chemicals, 55% are water treatment chemicals, and 58% are paper chemicals. a wide variety of best price of polyacrylamide options are available to you, such as classification, usage, and type.

factory supply anionic cationic nonionic polyacrylamide pam

anionic cationic nonionic polyacrylamide pam flocculant, water treatment chemicals manufacturer in china. chemicals raw materials polyacrylamide. water treatment chemicals

hot product flocculant polyacrylamide (pam),flocculants may not be unfamiliar to professionals who have been working with water treatment, but which flocculants are there, and how to distinguish and use them correctly seems a very confusing topic among many people. flocculant is a type of substance that can reduce or eliminate the precipitation stability and polymerization stability of dispersed particles in water, and make dispersed

south africa anionic polyacrylamide cas no. 9003-05-8 south

chemical auxiliary agent: appearance: white granule powder: molecular weight: 16-20million: cas no. 9003-05-8: package: one 20’fcl load in 18-20mt for usual: application: papermaking,sugar industries

flocculation of kaolin in water using novel calcium chloride,non-anionic polyacrylamide (pam), as a polymer flocculant, has been observed to bridge clay particles efficiently in the literature [8]. the reports of mpfou et al. [9] and lee et al. [10

- Can acrylamide based flocculants be used in oil sands extraction?

- A representative example comes from the effluents (tailings) of oil sands extraction process that contain high solids organic-contaminated fine clays, where the use of conventional acrylamide-based flocculants does not meet the dewatering criteria needed by this industry. 3

- What are inorganic and organic polymer flocculants?

- Inorganic flocculants can be divided into two systems of iron and aluminum, which have a good treatment effect on suspended solids and colloidal particles; organic polymer flocculants are mainly polyacrylamide and their derivatives, which have good treatment effects on suspended solids and coarse particles.

- Is polyacrylamide grafted hydroxypropyl methyl cellulose a biodegradable flocculant?

- Das R., Ghorai S., Pal S. Flocculation characteristics of polyacrylamide grafted hydroxypropyl methyl cellulose: An efficient biodegradable flocculant. Chem. Eng. J. 2013;229:144–152. doi: 10.1016/j.cej.2013.05.104. [ CrossRef] [ Google Scholar] 97.

- What is a polymer flocculant?

- Among the synthetic polymer flocculants, the most important is water-soluble polyacrylamide (PAM)—a non-ionic, amorphous polymer which can be modified to ionic form in the copolymerization process [ 8, 9, 10 ]. The acrylamide monomer can be used for grafting or crosslinking of other type of polymers.