- Classification: chemical auxiliary agent

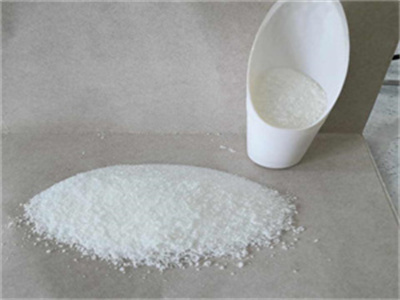

- Appearance: white powder/crystal

- CAS No.:9003-05-593

- Type: anionic,cationic,nonionic

- Formula: (C3h5no)N

- Solid Content: ≥87.5%

- Application:metallurgical mineral dressing industry

- Transport Package: 25 kg /per bag, 1 ton bag

- Delivery: 5-15days after deposit

polyacrylamide supplier distributor in philippines

polyacrylamide is used in irrigation water in agriculture to improve soil texture, sugar refining, where it can be used in beet or cane juice clarification. chemtradeasia is one of the largest supplier and distributor of polyacrylamide, we provide a wide range of chemical solutions in the philippines.

philippines polyacrylamide market for hot sale,philippines polyacrylamide market is expected to grow during 2024-2030

analysis of modified polyacrylamide by aqueous sec with low cost

samples: polyacrylamide eluent: 0.2 m nano 3 + 0.1 m nah 2 no 3, ph 7 conditions flow rate: 1 ml/min temperature: 40 ºc injection volume: 100 µl figure 1. raw triple detection data for a polyacrylamide 0 retention time (min) 22 refractive index viscometer 90 ° light scattering 15 ° light scattering 4.9 dlog m 6.9 1 0 dw/dlog m figure 2.

degradation of polyacrylamide and its significance in nature,acrylamide at a dose of 20 mg/kg/day stimulated the degeneration of peripheral nerves and the spinal cord of rats, although no obvious effects were found at doses less than 0.2 mg/kg/day. 152

best price polyacrylamide manufacturers and suppliers in philippines

looking for polyacrylamide manufacturers and suppliers in philippines, here we listed best price polyacrylamide manufacturers and suppliers in philippines. 1 polymer products (phil.) inc. pasig main branch address: 11 joe borris st., bagong ilog 1600, pasig, metro manila, philippines plus: h3cf+84 pasig, metro manila, philippines the introduction and subsequent education of polyester […]

chemicals polyacrylamide manufacturers latest price,find here polyacrylamide, 9003-05-8 manufacturers, suppliers exporters in india. get contact details address of companies manufacturing and supplying polyacrylamide, 9003-05-8 across india.

application of flocculants in wastewater treatment

as shown in table 1, many studies have proved that the addition of a polymeric flocculant to an inorganic coagulant showed better removal where it was effective in the reduction of environmental concerned parameters ( 90% generally) such as chemical oxygen demand (cod), total suspended solids (tss), turbidity and colour, reduce the amount of

synthesis and characterization of a novel cationic manufacturer.in this study, we investigated the method of a new cationic polyacrylamide flocculants. padd was prepared by uv initiation polymerization. the cationic flocculants were characterized by ftir, tg/ dsc, 1 h nmr and sem. therefore, results shows that padd and pam are not only simple physical mixtures, they have bond interaction and mutual

best price polyacrylamide suppliers and manufacturers

find polyacrylamide suppliers. get latest factory price for polyacrylamide. request quotations and connect with filipino manufacturers and b2b suppliers of polyacrylamide.

fabricating an anionic polyacrylamide (apam) with an anionic,fabricating an anionic polyacrylamide (apam) with an anionic block structure for high turbidity water separation and purification†. polyacrylamide white powder or granule,but water soluble polyacrylamide with alkali reaction, partially hydrolyzed polyacrylamide, under the strong acidity (pH ≤2.5) produce imidization, reduce its solubility in water.

chemical polyacrylamide water treatment polymer

polyacrylamide (abbreviated as pam or paam) is a polymer with the formula (-ch 2 chconh 2 -). it has a linear-chain structure. pam is highly water-absorbent, forming a soft gel when hydrated. in 2008, an estimated 750,000,000 kg were produced, mainly for water treatment and the paper and mineral industries.

polyelectrolyte polymers—types, forms, and function,the polyacrylamide use can be anionic, cationic, or nonionic with various ratios of the comonomers used in the case of the anionic and cationic polymers. the anionic polyacrylamide in the oil field industry are designated by the generic name of partially hydrolyzed polyacrylamide (phpa), although they are in actuality copolymers [80]. both

fabricating an anionic polyacrylamide (apam) with an anionic

ultraviolet (uv)-initiated template polymerization (utp) was used as a feasible strategy to prepare a novel anionic polyacrylamide (apam) with a microblock structure. in the template copolymerization system, acrylamide and sodium allylsulfonate (sas) were used as monomers, and poly (allylammonium chloride) (pa

polymer water treatment of flocculation polyacrylamide,cost: high emulsion polymer cationic, anionic, non-ionic molecular weight: up to 10 m (cationic), up to 20m (anionic, non-ionic) 30 -60% active polymer gel size: 0.1 -2 µm cost: high solution polymer (mannich) cationic only molecular weight: up to 10 m 4 -6% active cost: low limited usage 10 9 10

optimization conditions to obtain cationic polyacrylamide

the synthesis of cationic polyacrylamide (cpam) with the desired cationic degree and molecular weight is essential for various industries, including wastewater treatment, mining, paper, cosmetic chemistry, and others. previous studies have already demonstrated methods to optimize synthesis conditions to obtain high-molecular-weight cpam emulsions and the effects of cationic degrees on

polyacrylamide flocculant coagulant pam manufacturer,china polyacrylamide flocculant coagulant pam wholesale select 2024 high quality polyacrylamide flocculant coagulant pam products in best price from certified chinese water treatment flocculant manufacturers, flocculant for water treatment suppliers, wholesalers and factory on made in china.

saudi arabia polyacrylamide market by type, opportunities

growing use of polyacrylamide in the oil and gas industry for enhanced oil recovery, diverse applications of polyacrylamide apart from oil gas industry, increase in use of drilling and completion chemicals and growth in industrial activity in kingdom of saudi arabia are expected to drive the market growth. rising awareness and increasing

anionic / cationic polyacrylamide water treatment phpa high,5) flocculant: used widely for waste water treatment; industry sewage treatment, especially the sewage with high density, bit suspending granules, such as, the sewage of steel factory, electroplating factory, it has advantages of low cost and no pollution, also can be used in paper-making etc.

- What is coagulation–flocculation treatment process?

- Coagulation–flocculation process is regarded as one of the most important and widely used treatment processes of industrial wastewaters due to its simplicity and effectiveness. This paper provides a critical review on recent studies of coagulation–flocculation treatment processes of various industrial wastewaters.

- Can direct flocculation replace coagulation-flocculation in wastewater treatment?

- As presented above, direct flocculation has been applied to replace coagulation–flocculation in certain types of wastewater treatment. However, its application is mostly limited to organic-based wastewater with high concentration of suspended and colloidal solids; such as food, paper and pulp, and textile effluents.

- What are flocculating mechanisms in industrial wastewater treatment?

- Flocculating mechanisms: charge neutralisation, bridging and electrostatic patching. Flocculation is an essential phenomenon in industrial wastewater treatment. Inorganic coagulants (salts of multivalent metals) are being commonly used due to its low cost and ease of use.

- What are the different types of flocculants?

- Flocculants are divided into three groups: chemical, natural and grafted flocculants. Methods of wastewater treatment: coagulation–flocculation and direct flocculation. Flocculating efficiency of bio-flocculants is comparable to chemical flocculants. Flocculating mechanisms: charge neutralisation, bridging and electrostatic patching.