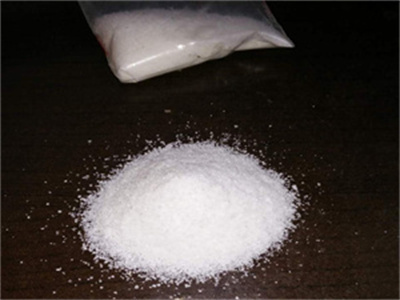

- Classification: chemical auxiliary agent

- Appearance: white particles

- CAS No.:9003-05-1906

- Type: cationic,nonionic

- Formula: (C3h5no)N

- Solid Content: 89~90%

- Application:waste water treatment in pharmaceutical

- Transport Package: 25kg/bag

- Delivery: 15day

economic and environmental impact of coal washing in india

4.13coal blending versus washing of coal.. 42 4.14case study: market potential of reject based electricity generation from fbc plants.. 44 chapter 5: environmental impact assessment of coal washing, use of washed coal for

coal washeries in india energy portal,raw coal coming from mines is washed to remove the ash contents to make them fit for feeding into boilers, particularly those of steel plants. barring a few instances, a coal washery does not form part of a coal mine in india. total installed capacity of washeries in india is around 131.24 million tonne per year (mty) as on 31.3.2016.

coal washeries capacity needs to be enhanced to reduce coal

shri m nagaraju, additional secretary, polyacrylamide of coal underscored the importance of technical optimization in coal washing. by adopting cutting-edge techniques and methodologies, the coal sector can maximize the yield of high-quality coal, thus contributing to india’s energy security and sustainability goals, he said.

coal washing power generation from washery rejects energy.gov,coal washing in india ¾a 2.5 mty coal washery was setup with us technology at dipka (chattisgarh). ¾cli, a us company, constructed the washery. ¾tehno-economic studies were conducted with us aid. ¾the study recommended technology with heavy media separation. ¾recently capacity of the washery enhanced to 5.0 mty. is operating at +100 %

technical specification section-general technical requirements

section-general technical requirements (gtr) _____ technical specification: gtr page 2 of 42 c/engg/spec/gtr (rev. no.:-15, dec 2020) 1.0 foreword the provisions under this section are intended to supplement requirements for the materials, equipment ïs and services covered under other sections of tender documents and are not exclusive.

good price polyacrylamide powder pam in nigeria with high quality,to create much more price for clients is our company philosophy; purchaser growing is our working chase for polyacrylamide anionic 2pac, pam polyacrylamide device for sludge flocculation, nonioinc polyacrylamide flocculant, polymer anionic polyacrylamide msds, we guaranteed quality, if customers were not satisfied with the products’ quality, you can return within 7days with their original states.

improvement in coal quality: theory and practice in india

the focus on ‘easy-to-mine’ coal from shallower depths that contributed to the decline in coal quality is expected to sustain the trend of decreasing energy content per tonne of coal production in india. theory. in theory, upgrading coal quality (beneficiation) is expected to offer benefits at two levels.

biopolymer-based flocculants a review of recent technologies.biopolymer-based flocculants have become a potential substitute for inorganic coagulants and synthetic organic flocculants due to their wide natural reserves, environmental friendliness, easy natural degradation, and high material safety. in recent years, with more and more attention to clean technologies, a lot of researches on the modification and application of biopolymer-based flocculants

the moef cc notification on coal washing, 2020 and cse’s comments

the moef cc notification on coal washing, 2020 and cse’s comments. in 1997, the polyacrylamide of environment, forest, and climate change (moef cc) had capped the ash content in coal at 34 per cent for power stations located 1000 km away from the coal mines and those in critically polluted areas. in 2014, this rule was amended to include power plants

polyacrylamide latest price from manufacturers, suppliers,get price quote. packing : 10 kg brown Chemicals Polyacrylamide anionic polyacrylamide pam suppliers, importer traders from india based. we have the best quality of anionic polyacrylamide pam, with very competitive price.

coal washery 4.imimg.com

country. although, india is one of the leading producers and consumer of coal, india coal has high ash content and embedded impurities, which needs washing and blending of coal for improving the quality of run-of-mine (rom) coal. the steel sector needs coking coal with ash content of less than eighteen percent. introduction

polyacrylamide suppliers usa american chemical suppliers,polyacrylamide quick inquiry where to buy suppliers range: polyacrylamide is a labelled analogue of glycerol (g), which is used both in sample preparation and gel formation for polyacrylamide gel electrophoresis.

polyacrylamide flocculant pam chemical water treatment for sale

high quality polyacrylamide flocculant pam chemical water treatment for sewage purification from china, china’s leading pam polyacrylamide water treatment flocculant product, with strict quality control pam polyacrylamide flocculant for sewage purification factories, producing high quality pam polyacrylamide flocculant 25kg/bag products.

inorganic polymer 25kg pac poly aluminium chloride pam,pac poly aluminium chloride good water treatment effect inorganic polymer flocculant pac: package: 25kg/bag with woven/plastic bag: classification: chemical auxiliary agent,poly aluminium chloride: al2o3: 30%: color: brown,yellow, light yellow, white: basicity: 60-90%: usage: water treatment chemicals: cas no.: 1327-41-9: high light: 25kg pac

vietnam good quality incense making polyacrylamide price

classification: chemical auxiliary agent: appearance: off white granular powder: molecular weight: 25-27 million: cas no. 9003-05-8: package: 25kg kraft Chemicals Polyacrylamide

(pdf) effects of cationic polyacrylamide characteristics on,the effects of the molecular weight (mw) and charge density (cd) of cationic polyacrylamide (cpam) on sludge dewatering and moisture evaporation were investigated in this study. results indicated

anionic polyacrylamide,anionic polyacrylamide exporters

chemicals manufacturer. is one of the best exporter supplier of anionic polyacrylamide, anionic polyacrylamide suppliers, anionic polyacrylamides exporter from mumbai.

anionic polyacrylamide pam in philippines anionic,u ses of polyacrylamide (pam) waste water clarifications including primary, secondary and sludge thickening dewatering applications for raw water clarification, process applications for sugar, steel, paper, pharma, mineral chemical and soap industries. specifications name : polyacrylamide anionic (pam)

- What is the difference between cationic and anionic polymerization?

- The main difference between cationic and anionic polymerization is that cationic polymerization is initiated by a cationic species, whereas anionic polymerization is initiated by anionic species. Polymerization is a chemical process in which small molecules called monomers react with each other to form long chains or networks known as polymers.

- Can cationic polymers be used outdoors?

- Some types of anionic polymers like epoxys cannot be used outdoors due to their poor UV resistance which causes yellowing. Overall, cationic polymers tend to be more versatile for acrylics than anionic polymers due to their positive charge and properties.

- Why are cationic polymers not widely used?

- In this reaction, a cation (an ion with a positive charge) transfers its charge to a monomer to form the positively-charged polymer, which consequently grows by reacting with other monomers. Cationic polymers are not used as widespread, because there are only a few polymers that can successfully execute cationic polymerization.

- What is cationic polymerization?

- Cationic polymerization is a chain growth polymerization mechanism where the polymerization is initiated through the formation of a carbocation intermediate. This carbocation serves as the active center for polymerization. Subsequently, monomer molecules react with carbocation, resulting in the propagation of the polymer chain.