- Classification: chemical auxiliary agent

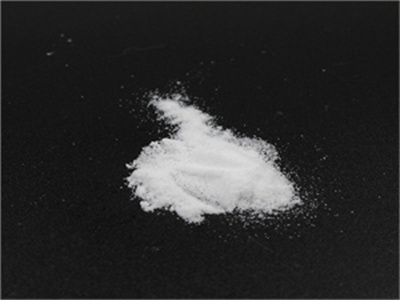

- Appearance: white particles

- CAS No.:9003-05-1940

- Type: cationic

- Formula: (C3h5no)N

- Solid Content: 89% Min

- Application:beneficiation,coal washing industries

- Transport Package: 25kg kraft paper bag

- Delivery: 3-5day

chemical flocculants polyacrylamide powder

flocculation is the process of agglomerating destabilized particles into bigger flocs. in wastewater flocculation and sludge treatment, colloidal particles are flocked in order to aid their removal or to help sludge dewatering. polymers can be used alone or together with inorganic coagulants to make flocs bigger and more resistant to shear forces.

how to select a chemical coagulant and flocculant,1% solution is defined as being 1% by weight, i.e 1g (or 1000 mg) of chemical in 99g (or 99 ml) of water for a total of 100g. 1 ml of this 1% solution will contain. 1 × 1000 mg 10 mg 100. this added to 1 litre is 10 mg per litre, or. 10 mgl-1 (or 10 ppm) thus 1g 1 ml 0.746 ml.

water soluble polymer flocculants synthesis

flocculants with less than 1% charged functional groups are considered as nonionic flocculants. 34 nonionic flocculants normally have high molecular weights, which helps them flocculate suspended particles through the bridging mechanism. 35 polyacrylamide is the most important water soluble nonionic flocculant because its monomer, acrylamide

polymer water treatment of flocculation polyacrylamide,polyacrylamide coagulants and flocculants theory and practice, Polyacrylamide is a polymer with white granule appearance, formed from acrylamide subunits. It can be synthesized as a simple linear-chain structure or cross-linked.. (1995) inversion of emulsion: water-in-oil oil-in-water 99% water polymer gel 30% oil oil polymer gel polymer 1 gal water 100 gal neat polymer 1.0%* polymer solution stabilizing surfactant especially important for clarifier at wtp strips “oil” off the

fact sheet water process solutions

polyacrylamide, april 2006. additional resources yong kim, coagulants and flocculants theory and practice, tall oaks ventures, littleton co, 2015. contact water process solutions ltd. unit 10 mill hall business estate aylesford kent, me20 7jz te: email:

wastewater treatment chemicals industrial use polymer,wastewater used cationic polyacrylamide|industrial|municipalwhite granular cationic polyacrylamide cpam can be widely used at waste water treatment(primary clarification, secondary tertiary treatment, dissolved air floatation) white cpam also can be used at sludge thickening sludge dewatering; high organic content or penicillin, erythromycin pharmaceutical waste water treatment.aries

degradation of polyacrylamide and its significance in nature

high quality flocculant polyacrylamide (pam) is commonly used as a flocculant in water and wastewater treatment, a soil conditioner, and a viscosity improver and friction enhancer.

anionic polyacrylamide pam in south africa- anionic.polyacrylamide (pam) poly acrylamide (polyelectrolyte / flocculants) applications of poly acrylamide industrial waste water treatment 1. sludge thickening 2. dewatering 3. colour removal 4. metallurgy 5. sewage treatment for various industries such as paper making 6. mining 7. coal mining 8. petroleum u ses of polyacrylamide (pam)

best practices guidance for the use of anionic polyacrylamide

pam aids solid-liquid separation by causing suspended particles to bind and form larger aggregates. the process is known as polymer bridging. one of the most common polymer flocculants on the market. common uses of pam as a flocculant: reduction of sediment and nutrient loads to natural lakes and ponds.

cheap price polyacrylamide powder pam ethiopia with high quality,classification: chemical auxiliary agent: appearance: white/light yellow granule or powder: molecular weight: 5-12 million: cas no. 9003-05-8: package: one 20’fcl load in 18-20mt for usual

biopolymer-based flocculants a review of recent technologies

biopolymer-based flocculants have become a potential substitute for inorganic coagulants and synthetic organic flocculants due to their wide natural reserves, environmental friendliness, easy natural degradation, and high material safety. in recent years, with more and more attention to clean technologies, a lot of researches on the modification and application of biopolymer-based flocculants

ethiopia best efficiency pam-nonionic polyacrylamide,a wide variety of anionic polyacrylamide price options are available to you, there are 2,356 anionic polyacrylamide price suppliers, mainly located in asia. the top supplying countries or regions are china, thailand, which supply 99%, 1% of anionic polyacrylamide price respectively. anionic polyacrylamide price products are most popular in. get

chemical polyacrylamide (PAM) flocculant types

polyacrylamide (pam) is a water-soluble linear polymer and one of the most widely used water-soluble polymer compounds.its derivatives find applications as efficient coagulants, thickeners, paper enhancers, and liquid friction reducers across various industries, including water treatment, papermaking, petroleum, coal, metallurgy, geology, textiles, and construction.

polyacrylamide pam flocculant for water treatment with best quality,cas no.: 9003-05-8 hs code: appearance: white powder ionic type: anionic, cationic, nonionic package: net 25kg / Chemicals Polyacrylamide with inner plastic bag description: according to ionic characteristics, it can be divided into four types, non-ionic polyacrylamide npam, anionic polyacrylamide apam, cationic polyacrylamide cpam and amphoteric polyacrylamide.

hot sale apam chemical powder water treatment potassium

water treatment chemicals- polyacrylamidewater treatment chemicals- polyacrylamide , find complete details about water treatment chemicals- polyacrylamide,water treatment chemicals,cationic water treatment chemical,cationic polymer from electronics chemicals supplier or manufacturer-gongyi city xianke water supply material co., ltd.in the drinking water and wastewater treatment, anionic

polyelectrolyte dynachem,polyelectrolyte-1000 is a liquid poly-cationic polymer of average molecular weight. it is recommended as a primary flocculent and coagulant in raw water clarification and lime softening.it is safe to use and meets all specifications for both fda and epa requirements for treatment of potable water at an application rate up to 20ppm maximum.

one-pot production of a graft copolymer of cationic starch

abstract. a newly developed, high-performance, and environmentally friendly flocculant, i.e., a graft copolymer of cationic starch and cationic polyacrylamide (sc-cpam), is synthesized via a single-step pathway in which the cationic agent is incorporated onto the starch backbone and into the polyacrylamide grafted branch simultaneously.

application of composite degradable modified starch-based,sludge dewatering is an important step for wastewater treatment. composite degradable flocculant (cdf) was prepared by cationic polyacrylamide (pam) grafting onto modified starch with a novel initiator, and characterized by fourier transform infrared spectroscopy.

- Is cationic Pam effective in flocculation?

- The success of anionic and cationic PAM in flocculation can be related to particle charges that allow for particle flocculation with polymers. Non-ionic PAM was shown to be ineffective at flocculating tailing particles. The ionicity of the polymer appears to be highly relevant here, based on the results.

- What is a Pam flocculating product?

- These flocculating products are used with active or passive BMPs. They’re exceptional on construction sites with slope or embankment washouts and where de-mucking sediment basins is required. With their negative charges, none of our PAM products change the water’s PH.

- How do high molecular weight PAMS work as flocculants?

- High molecular weight PAMs (10 6 to 10 7 g mol −1) work as flocculants by causing suspended particles to bind together to form larger aggregates, which can settle out quickly from solution leaving a clear supernatant (Heath et al. 2006 ).

- Does high mw anionic Pam outperform cationic polymers?

- The use of high MW anionic PAM in the flocculation of negatively charged particles outperforms cationic polymers by enhancing the settling rate and establishing a distinct sediment shape . Only minimal adsorption is possible due to electrostatic repulsion between kaolinite particles (which have a negative charge) and the polymer.