- Classification: chemical auxiliary agent

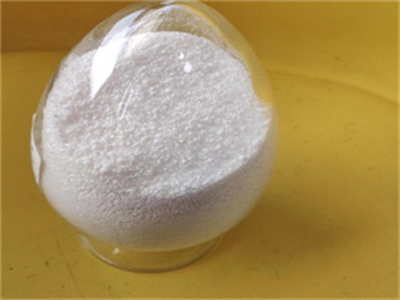

- Appearance: white fine-sand shaped powder or granule

- CAS No.:9003-05-2673

- Type: anionic,cationic

- Formula: (C3h5no)N

- Solid Content: ≥90%

- Application:drinking water treatment

- Transport Package: one 20’fcl load in 15-18mt palletized

- Delivery: 5-15days after deposit

coagulants vs flocculants comparing functions applications

2. organic coagulants: these are usually cationic or amphoteric polymers, which exhibit a high charge density, enabling them to neutralise particle charges and boost coagulation. 3. natural flocculants derived from plant, animal, or microbial sources, natural flocculants include chitosan, alginate, and starch.

flocculants types and where to use them aquatic technologies,flocculants are used across many industries including the food industry, brewing industry and water treatment industry. dissolved particles give water a “muddy” or “milky” appearance. dissolved particles in water can b dangerous as they often contain toxic minerals or harbour harmful microorganisms. flocculants are essential for proper

coagulation and flocculation in water treatment explained

the main purpose of coagulation and flocculation is to treat turbid (hazy or cloudy) water, thus improving water quality. this is especially key for wastewater treatment, and can reduce organic loads and suspended solids by up to 90%. suspended solids are commonly found in the majority of surface water supplies and all wastewater supplies.

water soluble polymer flocculants synthesis,flocculants with less than 1% charged functional groups are considered as nonionic flocculants. 34 nonionic flocculants normally have high molecular weights, which helps them flocculate suspended particles through the bridging mechanism. 35 polyacrylamide is the most important water soluble nonionic flocculant because its monomer, acrylamide

polymer water treatment of flocculation

emulsion: 6 months, un-opened drum/tote. dry: up to 3 years, un-opened bag. polymer solution: depends of concentration, water quality. storage temperature: 40 f 90 f. do not allow emulsion to freeze. once frozen, thaw in heated area and mix well. handling. wear latex gloves and eye protection.

preparation of cationic polyacrylamide suspension and its,solid particle cationic polyacrylamide (cpam) is one of the most commonly used organic polymer flocculants in oilfield wastewater treatment, but there are some problems, such as slow dissolution

coagulants and flocculants for water treatment manufacturer

veolia offers a comprehensive portfolio of coagulants and flocculants that aid in the clarification process. whether you need coagulants or flocculants, liquid, emulsion or powders, cationic or anionic products, veolia has a cost-effective solution for your raw water and wastewater. our application expertise ranges from operational optimization

polyacrylamide-grafted legume starch for wastewater treatment.polyacrylamide as traditional flocculant begins to draw the public awareness because of its non-biodegradable nature which may cause the long-term environmental degradation problems. a new high-efficient flocculant was synthesized by legume starch and acrylamide to satisfy the demand of coalmine wastewater treatment. grafting acrylamide onto mung bean starch was investigated and the

analysis and optimization of coagulation and flocculation

the time of macrofloc formation (flocculation time) is one of the operating parameters that is given great consideration in any water treatment plant that involves coagulation–flocculation operations. the turbidity reduction was observed to be prodigious at high rpm, i.e., 100–30 rpm at all ph ranges.

china cationic polyacrylamide suppliers, manufacturers,hot tags: cationic polyacrylamide, china, suppliers, manufacturers, factory, buy, price, made in china, cationic polyacrylamide flocculant, polyacrylamide for oil displacing agent, anionic polyacrylamide pam application, cationic polyacrylamide cas number, cationic polyacrylamide cpam , what is anionic polyacrylamide

coagulation–flocculation drinking water treatment polyacrylamide

the most commonly used procedure for treating surface water includes coagulation, flocculation, settling, filtration and disinfection. this combination of processes is used for treating a wide range of raw water qualities. not only does coagulation–flocculation make it possible to remove turbidity and suspended particles but also to reduce

chemicals polyacrylamide manufacturers latest price,find here polyacrylamide, 9003-05-8 manufacturers, suppliers exporters in india. get contact details address of companies manufacturing and supplying polyacrylamide, 9003-05-8 across india.

application of polyacrylamide flocculants for water treatment

in the present work, separation of silver ions from aqueous solutions by cuf using a novel complexation agent, namely anionic polyacrylamide (average molecular weight 50 kda) and a

cationic flocculant at best price in india,find here online price details of companies selling cationic flocculant. get info of suppliers, manufacturers, exporters, traders of cationic flocculant for buying in india.

cationic polyacrylamide: synthesis and application in sludge

among popularly used chemical coagulants, high-molecular-weight synthetic polymers have been widely employed as flocculants in colloidal suspensions to separate and dewater solid/water systems [2,3].

anionic chemical polyacrylamide with good price,anionic polyacrylamide with high molecular weight and good solubility polyacrylamide flocculant can be an important kind of flocculants. and it has been widely used in water treatment because of good flocculation performance . generally, molecular weight of polysaccharide polymer is determined by intrinsic viscosity.

top 10 polyacrylamide manufacturers and suppliers in india

looking for polyacrylamide manufacturers and suppliers in india, here we listed top 10 polyacrylamide manufacturers and suppliers in india. polyacrylamide is a linear water-soluble polymer, and is one of the most widely used varieties of water-soluble polymer compounds.

preparation of cationic polyacrylamide suspension and its,cationic polyacrylamide (cpam) solid particle is one of the most commonly used organic polymer flocculants in oilfield wastewater treatment, but it poses some problems, such as a slow dissolution rate and an easy formation into a fish-eye in the process of diluting into aqueous solution.

- What factors affect the flocculation effect of cationic polyacrylamide (CPAM)?

- Cationic polyacrylamide (CPAM) is a commonly used flocculant for water treatment. Factors that affect the flocculation effect and can be controlled manually include the type and dosage of CPAM, wastewater pH, stirring time and settling time, and their reasonable setting is critical to the flocculation effect of CPAM.

- What is organic polymer flocculant cationic polyacrylamide (CPAM)?

- The organic polymer flocculant cationic polyacrylamide (CPAM) has the characteristics of a low additive amount, good turbidity removal and water purification effect, and high COD removal efficiency, and it has become the most commonly used polymer flocculant in the oilfield wastewater treatment process .

- Can cationic polyacrylamide be used in oilfield wastewater treatment?

- Author to whom correspondence should be addressed. Cationic polyacrylamide (CPAM) solid particle is one of the most commonly used organic polymer flocculants in oilfield wastewater treatment, but it poses some problems, such as a slow dissolution rate and an easy formation into a “fish-eye” in the process of diluting into aqueous solution.

- What is cationic polyacrylamide (CPAM) adsorption behavior?

- Cationic polyacrylamide (CPAM), a typical drilling fluid shale inhibitor can prevent the clay swelling and maintain the wellbore stable. Understanding the adsorption behavior of CPAM on montmorillonite (MMT) surfaces is of great significance in explaining the excellent performance of cationic inhibitors.