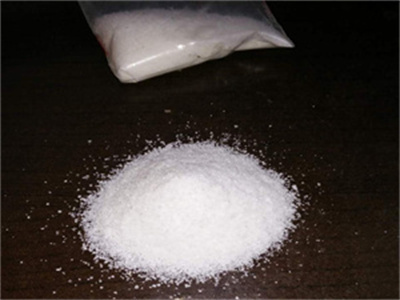

- Classification: chemical auxiliary agent

- Appearance: white granule/power

- CAS No.:9003-05-2975

- Type: cationic

- Formula: (C3h5no)N

- Solid Content: ≥91%

- Application:sand prevention solidification industry

- Transport Package: 25kg/bag, 1000kg/bag, customized package

- Delivery: 3-5day

polyacrylamide in coal washing plant testing. #watertreatment

coal washing, also known as coal beneficiation, is the process of removing impurities from raw coal to improve its quality and suitability for various applic.

synthesis and evaluation of cationic polyacrylamide flocculant,however, nguyen et al., [32] observed high flocculation efficiency of marine microalgae phaeodactylum tricornutum with a cationic polyacrylamide flocculant (fo3801). the discrepancy in the literature suggested that a future flocculation study using one type of polymer with multiple marine species. 4. conclusions

polyacrylamide treatment of coal washing wastewater youtube

the video demonstrates the application effect of polyacrylamide in sewage treatment through experiments on coal washing sewage. in some industries that use a.

nonionic polyacrylamide polymer polyacrylamide,20tons/20gp container(without pallet) 4. application. 1) coal washing: nonionic polyacrylamide can be used for the centrifugal separation of the coal washing tailing, used in the sediment, and the filtration processes of the coal dust and the coal slurry. it can help to improve the recovery rate of the coal dust and the filtration rate.

treatment of coal washing wastewater with polyacrylamide

coal taken directly from a mine is called raw coal. raw coal is mixed with many impurities in the process of mining, and the quality of coal is different. coal with small inner ash and large inner ash are mixed together. for the treatment of coal washing wastewater, we suggest using polyacrylamide to treat coal washing wastewater.

a review of nano-based materials used as flocculants for sale,in recent years, the development of nanoparticle materials for water treatment has received great attention. from an industrial technological view point, the application of nanomaterials in the twenty-first century for water treatment will be the focal point of advanced materials design, processing and progress. in this context, the potential utilisation of different types of flocculants to

how anionic and cationic polyacrylamide used in coal washing

of course, there are special circumstances, and non-ionic polyacrylamide and cationic polyacrylamide can also be used according to water quality needs. when washing coal in a coal washing plant, first add the dissolved polyaluminum chloride solution to the raw coal washing water, start stirring, about 10 seconds, then add the dissolved anionic

recent advancement of coagulation–flocculation and its.increasing environmental awareness coupled with more stringent regulation standards has triggered various industries to challenge themselves in seeking appropriate wastewater treatment technologies. coagulation–flocculation process is regarded as one of the most important and widely used treatment processes of industrial wastewaters due to its simplicity and effectiveness. this paper

application and precautions of zhengda polyacrylamide in coal

the speed of the leaf line depends on the container. two. add: dilute the special flocculation agent for washing coal and dilute it with water. the concentration is between 0.02 and 0.2%, and the flow rate is evenly added to the coal slurry water by the valve. (the concentration can be directly prepared between 0.02 and 0.2%. the solution).

cationic polyacrylamide copolymers (pam): environmental half,background cationic polyacrylamide copolymers (pam) are used for sludge dewatering in municipal waste water treatment and might enter the environment by spreading of the sludge on agricultural land. concern has been expressed since little is known about the degradation of pam in soils. to obtain detailed information on the polymer’s fate in the soil compartment, the degradation of 14c

anionic polyacrylamide waste water chemical supplier

in coal industry, anionic polyacrylamide is used as coal-washing additive. anionic polyacrylamide has generally two ways of preparation, one is copolymerization, which was prepared by the copolymerization of acrylamide and acrylic acid or sodium acrylate aqueous solution; the other is the chemical conversion method, that is, from partial

application of fecl3 to adjust urban sewage-dewatered sludge,the urban sewage-dewatered sludge (udss) containing cationic polyacrylamide is difficult to dewater. fecl3 was used as conditioner to adjust the udss. to investigate the effect and principle, the polyacrylamide of udss were evaluated in terms of dewatering equipment, micro electrophoresis, malvern laser particle size polyacrylamide, nuclear magnetic resonance polyacrylamide, and scanning

biopolymer-based flocculants a review of recent technologies

biopolymer-based flocculants have become a potential substitute for inorganic coagulants and synthetic organic flocculants due to their wide natural reserves, environmental friendliness, easy natural degradation, and high material safety. in recent years, with more and more attention to clean technologies, a lot of researches on the modification and application of biopolymer-based flocculants

wastewater treatment technologies,the majority of wastewater treatment methods can be categorized into two main groups: biological treatment and chemical/physical treatment. the first technique utilizes biological material and/or bacteria, and the second is based on physical processes or chemical reactions.

25kg bag anionic polyacrylamide price in south africa

item: anionic flocculant polymer sodium acrylate anionic polyacrylamide origin: china packaging: 25 kg / bag 1 kg / pe bag. china anionic polymer, anionic polymer manufacturers.einecs : 201-173-7. acid-base polyacrylamide flocculant : neutral surface disposal agent. henan lvyuan water treatment technology co., ltd. inquiry basket. 1 / 6.

pam chemical auxiliary cationic polyacrylamide flocculant,high quality pam chemical auxiliary cationic polyacrylamide flocculant polymer white grain powder from china, china’s leading cationic polymer white grain powder product, with strict quality control pam chemical auxiliary agent powder factories, producing high quality cationic polyacrylamide white grain powder products.

industrial chemical detergent raw material anionic polyacrylamide

industrial chemical detergent raw material anionic polyacrylamide, find details and price about polyacrylamide pam from industrial chemical detergent raw material anionic polyacrylamide zhengzhou jiasheng water purification material co., ltd.

cas no. 9003-05-8 cationic anionic polyacrylamide polymer pam,cas no. 9003-05-8 cationic anionic polyacrylamide polymer pam powder coagulant water treatment flocculant, find details and price about free sample polyacrylamide granules polyacrylamide flocculant price from cas no. 9003-05-8 cationic anionic polyacrylamide polymer pam powder coagulant water treatment flocculant weifang js trading co., ltd

- What is polyacrylamide (PAM) used for?

- High molecular weight polyacrylamide (PAM) is commonly used as a flocculant in water and wastewater treatment, a soil conditioner, and a viscosity improver and friction reducer in enhanced oil recovery and high-volume hydraulic fracturing.

- What is high molecular weight polyacrylamide (PAM)?

- Supplied by Our Company High molecular weight polyacrylamide (PAM) is commonly used as a flocculant in water and wastewater treatment, a soil conditioner, and a viscosity improver and friction reducer in enhanced oil recovery and high-volume hydraulic fracturing.

- How is the polyacrylamide (PAM) market performing in 2024?

- Track polyacrylamide (PAM) price trends and forecasts for the top ten countries worldwide. North America, quarter ending March 2024 The North American polyacrylamide (PAM) market continued to decline in the first quarter of 2024, with prices falling to $2,375 per metric ton (FOB - Texas) by the end of March.

- How can polyacrylamide and inorganic flocculants improve water quality?

- Improve water quality. In drinking water treatment and industrial wastewater treatment, the combined use of polyacrylamide and inorganic flocculants can significantly improve water quality. Improve the strength and settling speed of flocs.