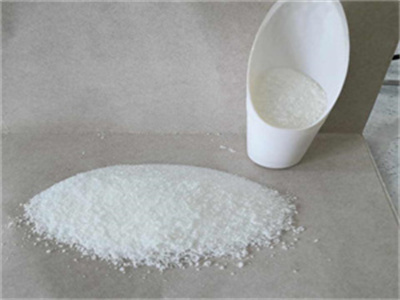

- Classification: chemical auxiliary agent

- Appearance: white fine-sand shaped powder or granule

- CAS No.:9003-05-3302

- Type: anionic,cationic,nonionic

- Formula: (C3h5no)N

- Solid Content: ≥88%

- Application:coal washing,metallurgy industries

- Transport Package: one 20’fcl load in 18-20mt for usual

- Delivery: 3-7day

recent advances of modified polyacrylamide in drilling

previous studies have shown the effectiveness of rheology modifier in drilling fluid. for instance, balding et al. (2020) studied the water-based drilling fluid formulation with various formulations via free radical grafting and physical blending with chemical additives, such as polystyrene sulfonate (pss), polyacrylamide (pam), cellulose nanocrystal (cnc), and modified cnc with vinyl

preparation of low-molecular-weight polyacrylamide as the,deep wells and ultra-deep wells often encounter cracks, karst caves, and other developed strata, which can lead to leakage during drilling. conventional bridge slurry plugging technology is prone to leaking due to the poor plugging effect of the plugging agent. the gel plugging agent possesses characteristics of flexible plugging and adaptive matching of formation leakage channels. it can fill

trends in polyacrylamide utilization and treatment for sale

pam plays increasingly important roles in the oil and gas industry. among a wide range of polymers, pam, and its derivatives are extensively employed in hf fluid (table 1).the usage of pam (5.6

degradation of polyacrylamide and its significance in nature,high quality flocculant polyacrylamide (pam) is commonly used as a flocculant in water and wastewater treatment, a soil conditioner, and a viscosity improver and friction enhancer.

phpa manufacturers india partially hydrolyzed polyacrylamide

phpa (partially hydrolyzed polyacrylamide) powder should be added in fresh water to get a highly viscous drilling fluid in delhi. the marsh funnel viscosity for clay or shale formation should be ≥ 50 seconds per quart and ≥ 60 seconds per quart for sandstone or unconsolidated sand. soluble up to 20 gm per liter giving viscous solution.

polyacrylamide (pam) prices wholesale flocculant,polyacrylamide (pam) is a water-soluble polymer, physically available as a white crystalline solid. it is a non-ionic compound which forms strong hydrogen bonds with water molecules and hence capable to retain water. this water absorbing and retention quality makes it suitable to be used as a super absorbent.

preparation and properties of cationic polyacrylamide

polyacrylamide (pam) are an important class of water-soluble polymers with low synthetic cost, high viscosity, and good rheological properties. pam is widely used for oil and gas extraction and wastewater treatment industries, especially in drilling fluids, fracturing fluids, polymer drives and other oil and gas extraction fields.

polyacrylamide (pam) market size, share, trends forecast.the global market size of polyacrylamide (pam) is expected to rise in the upcoming years and reach approximately 4200 thousand tonnes by 2032. q2. which end-use industry is dominating the global polyacrylamide (pam) market? ans: the water treatment industry is dominating the polyacrylamide (pam) market with a market share of 35% in 2022. q3.

recent advances of modified polyacrylamide in drilling

lesser water content in drilling fluid can minimise the shale swelling. in contrary, high water content in drilling fluid may have drawbacks such as high shale, friction, and mud filtrate volume with low plastic viscosity. this leads to the wellbore instability issue (aftab et al., 2017). drilling fluid with low solid content may have high water.

high molecular nonionic polyacrylamide flocculating agent,high quality high molecular nonionic polyacrylamide flocculating agent npam powder from china, china’s leading poly aluminium chloride coagulant 25kg/ bag product, with strict quality control 215-477-2 poly aluminium chloride coagulant factories, producing high quality einecs no 215-477-2 pac coagulant products.

research on a new cationic polyacrylamide (cpam manufacturer

flocculation is a common method to improve filtration efficiency and purify water quality in water supply plants where the commonly used flocculant is cationic polyacrylamide (cpam) (vandamme et al. 2010; teh et al. 2016). for sludge dewatering, cpam shows superior conditioning performance and obtained more and more attention.

high molecular nonionic polyacrylamide flocculating agent,high quality high molecular nonionic polyacrylamide flocculating agent npam powder from china, china’s leading poly aluminium chloride coagulant 25kg/ bag product, with strict quality control 215-477-2 poly aluminium chloride coagulant factories, producing high quality einecs no 215-477-2 pac coagulant products.

what is hot sale cheap price stock good quality petrochemical

what is hot sale cheap price stock good quality petrochemical materials factory price anionic polyacrylamide, pam manufacturers suppliers on video channel of made in china..

degradation of polyacrylamide and its significance in nature,application of 1–20kg of polymer per hectare (ha),33,34 with typical mw of 1–20×106 da21 ,3335 and concentrations less than 10mg/l;33 the high cost of pam is a significant limitation to more

wastewater treatment agent pam polyacrylamide

cas no 9003-05-8 cationic polyacrylamide cpam water treatment white granule food grade cationic polyacrylamide cpam water soluble cationic pam cas no. 9003-05-8 polyacrylamide pam sewage water treatment chemicals anionic polyacrylamide apam industry use anionic polyacrylamide apam papermaking to improve paper

improvement of rheological, filtration and thermal,high/ultra-high temperatures (ht/uht) in deep strata seriously deteriorate the comprehensive performance (such as weak setting stability, poor suspension stability and excessive filtration loss) of oil-well cement (owc) slurry due to the degradation and group variation of polymer admixtures (retarder, fluid loss additive, dispersant and suspension stabilizer) with high dosage, seriously

preparation and properties of cationic polyacrylamide

sio2 particles of different particle sizes were prepared by sol–gel method using ethyl orthosilicate (teos) as raw material. nano-silica/cationic polyacrylamide (cpam) prepared by inverse emulsion polymerization of modified silica (c-sio2) as a hydrophobic component with acrylamide (am), dimethyl diallyl ammonium chloride (dmdaac) and methacryloyloxyethyl trimethyl ammonium chloride (dmc

(pdf) synthesis and application of polyacrylamide grafted,journal pre-proof synthesis and application of polyacrylamide grafted magnetic cellulose flocculant for palm oil wastewater treatment mohamed hizam mohamed noor (conceptualization) (methodology) (investigation) (writing original draft), norzita ngadi (validation) (resources) (supervision), ibrahim mohammed inuwa (writing review and editing

- Can cationic polyacrylamide be used in oilfield wastewater treatment?

- Author to whom correspondence should be addressed. Cationic polyacrylamide (CPAM) solid particle is one of the most commonly used organic polymer flocculants in oilfield wastewater treatment, but it poses some problems, such as a slow dissolution rate and an easy formation into a “fish-eye” in the process of diluting into aqueous solution.

- Are cationic polyacrylamide copolymers used for sludge dewatering?

- Cationic polyacrylamide copolymers (PAM) are used for sludge dewatering in municipal wastewater treatment and may enter the environment through the spread of sludge on agricultural fields.

- What are cationic polyacrylamide copolymers?

- Cationic polyacrylamide copolymers (PAM) are a group of water-soluble polymers with a wide range of applications in industry, food processing, agriculture and waste management. One of the major applications for PAM is sludge dewatering in municipal waste water treatment plants (MWWTPs).

- Can cationic polyacrylamide flocculants be used to treat oily water?

- Shu, G., Bu, K., Zhao, B. Zheng, S. Evaluation of newly developed reverse demulsifiers and cationic polyacrylamide flocculants for efficient treatment of oily produced water. Colloids Surf. A 610, 125646 (2021). This work was supported by grants from the “Qihang Program” of the Southwest Petroleum University (2023QHZ001) awarded to C.Z.