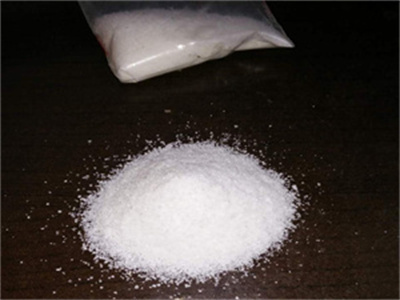

- Classification: chemical auxiliary agent

- Appearance: off-white granular powder

- CAS No.:9003-05-2496

- Type: anionic

- Formula: (C3h5no)N

- Solid Content: 88.5% Min

- Application:sewage water treatment industry

- Transport Package: 25kg kraft paper or customization

- Delivery: 15day

polymer water treatment of flocculation polyacrylamide

aging –use of tap water vs reclaimed water 400 600 800 1000 1200 1400 1600 0 100 viscosity, cp aging time, min cationic 0.5%, clarifloc c-9545 tap water w3 600 1100 1600 2100 2600 3100 0 2040 6080 100 aging time, min anionic 0.5%, drewfloc 2270 tap water w3 viscosity of polymer solution with reclaimed water: significantly lower

water treatment polymers high quality polyacrylamide,municipal water treatment: water treatment polymers are extensively used in municipal water treatment plants for processes like coagulation, flocculation, sedimentation, and filtration to remove impurities and contaminants from drinking water. industrial water treatment: industries such as chemical processing, power generation, food and

flocculants for water treatment balancing safety flocculant

natural and synthetic cationic flocculants are effective for water treatment but carry a high toxicity to aquatic organisms (liber et al. 2005, wa doe 2019). anionic polymers have 10-100x lower toxicity than cationic polymers (with the same effective rate) and are therefore the first choice of states regulatory agencies for environmental

synthetic polymeric flocculants aid dewatering water technology,synthetic polymeric flocculants aid dewatering. march 1, 2000. most flocculants in use today are synthetic water soluble polymers based on acrylamide and its derivatives and which may include either anionic or cationic groups in a wide range of molecular weights and charge densities. they are supplied as dry powders or in liquid form as liquid

coagulation and flocculation for raw water ecolab

coagulation and flocculation involve the removal of suspended solids and turbidity from water to prepare it for use or for further treatment. this step typically uses the difference in density between the water and the suspended material for separation. the process of coagulation, along with flocculation, is used whenever the natural settling

performance of pam/pei gel system for water shut‐off in high,the thermal stability of the pam/pei polymeric gel in saline water was examined at 150°c (302f). samples prepared in sea water showed better stability compared with distilled and field water. dynamic rheology and core-flooding experiments were used to evaluate the pam / pei gel system at high temperatures.

water soluble polymer flocculants synthesis

in a more precise classification, if the charges are introduced by copolymerizing cationic and anionic monomers, the polymer is called amphoteric, whereas if the polymer is made of a monomer that has both cationic and anionic groups (overall zero charge), it is called zwitterionic or betaines. 40 comprehensive reviews on this special class of

flocculant waste water treatment polyacrylamide pam high.ach ck series have obtained sirim’s product certification (ms1454:2007) and registered with national polyacrylamide polymer powder commission or span for used in water treatment services. it is also halal certified by jakim malaysia.,poly aluminum chloride vs. aluminum sulfate: a deep dive in this article, we will delve into the comparison between two

polymers emulsions and powder coagulant aids accepta ltd

accepta polymers (pam) have been developed to suit a wide variety of wastewater treatment and effluent treatment applications and includes structured polymers, co-polymers; and low, medium, high and very high molecular weight cationic and anionic polymers in both liquid/emulsion and dry/powder forms. polyelectrolytes (most often referred to as

25kg bag anionic polyacrylamide price in south africa,polyacrylamide pam flocculant for water treatment chemate. polyacrylamide pam powder. cas no.: 9003-05-8. hs code: . appearance: white powder.

polymer based flocculants review of water purification

examples of some of the findings in the literature on the subject of using polymer flocculants are: anionic flocculant is more effective at increasing the settling speed of slurries than cationic and non-ionic flocculants; when the ph, flocculant dosage, and shear rate rose, the relative flocculation rate increased at first and subsequently

design of amazon polyacrylamide crystals in south africa,water gel crystals, also known as water jelly crystals and super absorbent polymer, are able to absorb up to 400 times their weight in water. place 1 teaspoon (4g) of these small 2-4mm crystals in a quart of water, let it sit overnight, pour off the excess water and you will have over 2 cups of beautiful, large 1-2 jelly-like clear crystals.

polyacrylamide (pam) prices wholesale flocculant

pam prices high molecular weight cationic anionic polyacrylamide. europe. in the first quarter of 2023, the german market witnessed a substantial rise in polyacrylamide (pam) prices due to increased demand from downstream industries and a surge in import prices reaching european shores.

pam (anionic polyacrylamide) industrial chemical products,pam, or anionic polyacrylamide, is a very long chain, high molecular weight organic polymer produced from natural gas, with characteristics which make it useful as a soil amendment to control runoff and soil loss. the chemical when applied as a liquid solution to a freshlytilled soil surface will

what are pam and pac in sewage treatment? what’s the use?

pam appearance is white powder, soluble in water, almost insoluble in benzene, ether, esters, acetone and other general organic solvents, polyacrylamide aqueous solution is almost transparent

directory of suppliers manufacturers in world volza.com,these facts are updated till 2 aug 2024, and are based on volza’s global suppliers manufacturers directory of , sourced from 70 countries export import shipments with names of buyers, suppliers, top decision maker’s contact information like phone, email and polyacrylamide profiles.

polyacrylamide powder pam in iraq high purity polyacrylamide

factory supply 187 polyacrylamide food grade pam products. about 29% of these are paper chemicals, 27% are petroleum additives, and 20% are leather auxiliary agents. a wide variety of polyacrylamide food grade pam options are available to you, such as coating auxiliary agents, petroleum additives, and water treatment chemicals.

high purity polyacrylamide gel electrophoresis (sds‐page),in polyacrylamide gel electrophoresis, proteins migrate in response to an electrical field through pores in a polyacrylamide gel matrix; pore size decreases with increasing acrylamide concentration. the combination of pore size and protein charge, size, and shape determines the migration rate of the protein.

- What is the global polyacrylamide market size?

- The global polyacrylamide market size was estimated at USD 5.5 billion in 2022 and is expected to reach USD 5.8 billion in 2023. What is the polyacrylamide market growth? b. The global polyacrylamide market is expected to grow at a compound annual growth rate of 6.5% from 2023 to 2030 to reach USD 9.1 billion by 2030.

- What is the economics of polyacrylamide production from acrylamide?

- This report presents the economics of Polyacrylamide production from acrylamide. The process examined is a typical aqueous solution polymerization. The primary objective of this study is to explain the cost structure of the aforementioned process, encompassing capital investment and operating cost figures.

- How will polyacrylamide market growth impact the water treatment industry?

- The rising demand for polyacrylamide to treat municipal sewage, industrial wastewater, and drinking water purification plants is expected to propel demand. Furthermore, increasing attention to the water treatment industry by government regulatory bodies across various countries is likely to have a positive impact on market growth.

- How is polyacrylamide powder obtained?

- The process examined is a typical aqueous solution polymerization. In this process Polyacrylamide Powder is obtained as the final product. The report examines one-time costs associated with the construction of a plant and the continuing costs associated with the daily operation of such a plant.