- Classification: chemical auxiliary agent

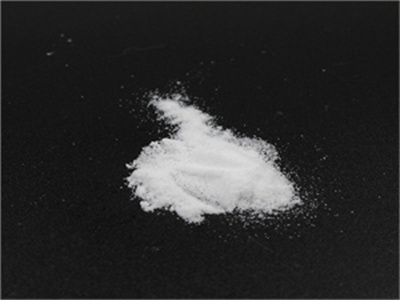

- Appearance: white to off-white crystalline granular

- CAS No.:9003-05-2342

- Type: anionic,nonionic

- Formula: (C3h5no)N

- Solid Content: ≥88.5%

- Application:textile industries

- Transport Package: 25kg kraft paper or customization

- Delivery: 3-7day

degradation of polyacrylamide and its significance in nature

high quality flocculant polyacrylamide (pam) is commonly used as a flocculant in water and wastewater treatment, a soil conditioner, and a viscosity improver and friction enhancer.

water soluble polymer flocculants synthesis,they are used in mineral processing, industrial and municipal wastewater treatment, oil sands tailings dewatering, paper making, and biotechnology. 1-4 this work reviews different kinds of water soluble flocculants, focusing on advances in synthesis, characterization, and performance assessment in solid–liquid separation in mineral processing

optimizing the flocculation effect of cationic polyacrylamide

cationic polyacrylamide (cpam) is a commonly used flocculant for water treatment. factors that affect the flocculation effect and can be controlled manually include the type and dosage of cpam, wastewater ph, stirring time and settling time, and their reasonable setting is critical to the flocculation effect of cpam. in this paper, the optimal flocculation conditions of a novel cpam were

cationic polyacrylamide emulsion with ultra-high,in addition, the cationic polyacrylamide emulsion with high molecular weight has better flocculating effect, which may be due to the greater bridging effect of the high molecular weight cationic polymer chai (wong et al. 2006). that is to say, when the same treatment effect is achieved, the required amount of cationic polyacrylamide emulsion

research on a new cationic polyacrylamide (cpam) with high quality

flocculation is a common method to improve filtration efficiency and purify water quality in water supply plants where the commonly used flocculant is cationic polyacrylamide (cpam) (vandamme et al. 2010; teh et al. 2016). for sludge dewatering, cpam shows superior conditioning performance and obtained more and more attention.

polyacrylamide,cationic polyacrylamide exporters mumbai,cationic polyacrylamide is mainly used in industrial solid-liquid separation process, including settlement, clarification, concentration, and sludge dewatering processes. . the major uses include urban sewage treatment, paper making, food processing, petrochemical, metallurgical, mineral dressing, dyeing, sugar making and all kinds of industrial waste water treatme

optimization conditions to obtain cationic polyacrylamide

the synthesis of cationic polyacrylamide (cpam) with the desired cationic degree and molecular weight is essential for various industries, including wastewater treatment, mining, paper, cosmetic chemistry, and others. previous studies have already demonstrated methods to optimize synthesis conditions to obtain high-molecular-weight cpam emulsions and the effects of cationic degrees on

global polyacrylamide market by form (liquid, solid), type.figure 5. polyacrylamide market size, by region, 2023 vs 2024 vs 2030 (usd million) figure 6. polyacrylamide market dynamics figure 7. polyacrylamide market size, by form, 2023 vs 2030 (%) figure 8. polyacrylamide market size, by form, 2023 vs 2024 vs 2030 (usd million) figure 9. polyacrylamide market size, by type, 2023 vs 2030 (%) figure 10.

optimization conditions to obtain cationic polyacrylamide

previous research, such as the studies by ma et al., successfully synthesized cpam with cationic degrees of up to 40 percent for the treatment of wastewater with high kaolin content [8,9]. fu et al. optimized cpam dosage, stirring time, and wastewater ph for flocculation of kaolin-based wastewater using the response surface methodology [ 10 ].

anionic polyacrylamide (pam) application,conservation practice standard anionic polyacrylamide (pam) application (code 450) author: usda nrcs subject: conservation practice standard for use in usda nrcs programs keywords: nrcs, anionic polyacrylamide (pam) application, 450, irrigation, polyacrylamide, pam created date: 8/20/2020 6:53:57 pm

continuous low dosing of cationic polyacrylamide (pam) price

a conical water tank (total volume: 1.3 m 3) was used to make up and store as few day supply of cationic polyacrylamide (pam, crystalfloc b 490 h: 90% active ingredient cationic polyacrylamide, ixom ltd) (figure 2). a submersible mixer (0.7 kw amd 4 pole direct drive mixer) with a variable speed drive was installed onto a metal frame over the

(pdf) synthesis, characterization, and flocculation,in this study, a kind of anionic polyacrylamide (p(am-aa-amps)) was synthesized using acrylamide, acrylic acid (aa), and 2-acrylamido-2-methyl propane sulfonic acid (amps) under ultraviolet

white cationic polyacrylamide cpam high purity for water

high quality white cationic polyacrylamide cpam high purity for water drilling industry from china, china’s leading white cationic polyacrylamide cpam product, with strict quality control high purity cpam chemical factories, producing high quality water drilling industry cpam chemical products.

algeria free sample polyacrylamide food grade with high quality,classification: chemical auxiliary agent: appearance: white particles: molecular weight: 12-16 million: cas no. 9003-05-8: package: 25kg kraft Chemicals Polyacrylamide: application

anionic polyacrylamide cationic anionic polyacrylamide

synonyms: anionic polyacrylamide 3 physico-chemical properties polyacrylamide polymers can exist in cationic, anionic or non-ionic forms, depending on their ionic charge. the non-ionic form of polyacrylamide is generated from the basic polymerisation of acrylamide. anionic polyacrylamide polymer can then be formed from the hydrolysis of the

south korean zinc suppliers and manufacturers with high quality,request quotations and connect with south korean manufacturers and b2b suppliers of zinc. south korea (republic of korea) 800kg to 900kg per a pallet and 22

applying rheological analysis to understand the mechanism of sale

mechanism of polyacrylamide (pam) conditioning for sewage sludge dewatering hou-feng wang, a hua-jie wang,ab hao hua and raymond j. zeng*a nowadays, polyacrylamide (pam) is widely used for sludge conditioning, while the interactions between pam and sludge particles influencing the dewatering process remain to be clarified. this study focused

zimbabwe best efficiency pam anionic polyacrylamide,2. water treatment chemicals,anionic pam: it is widely used in waste water . cationic polyacrylamide flocculant for chemical flocculant polyacrylamide. cationic polyacrylamide flocculant used in chemical flocculant polyacrylamide sludge dewatering treatment . description: blufloc c8030 is high molecular weight cationic polyacrylamide, used for different kinds of sludge dewatering

- What factors affect the flocculation effect of cationic polyacrylamide (CPAM)?

- Cationic polyacrylamide (CPAM) is a commonly used flocculant for water treatment. Factors that affect the flocculation effect and can be controlled manually include the type and dosage of CPAM, wastewater pH, stirring time and settling time, and their reasonable setting is critical to the flocculation effect of CPAM.

- What are cationic flocculants used for?

- Cationic flocculants are normally used to flocculate negatively charged particles, and are used in wastewater and sludge treatment, paper production, oily water clarification, textile industry, paint manufacturing, dairy processing, and biotechnology. Compared to nonionic monomers, cationic monomers are less accessible and stable.

- How effective is PAMC flocculation in turbid water clarification?

- Chemical and morphology structures of PAMC were characterized and analyzed. Flocculation performance and kinetics were investigated in highly turbid water clarification. Most effective flocculation occurred at pH 4 with the flocculant which contained the highest cationic content.

- Is acrylamide a cationic flocculant?

- The copolymer of acrylamide (AM) and DMC is used as an effective cationic flocculant in wastewater treatment. A series of copolymers of AM and DMC (PAMC) were synthesized using different approaches. In earlier studies, γ-ray irradiation with inverse emulsion polymerization was employed to copolymerize AM and DMC .