- Classification: chemical auxiliary agent

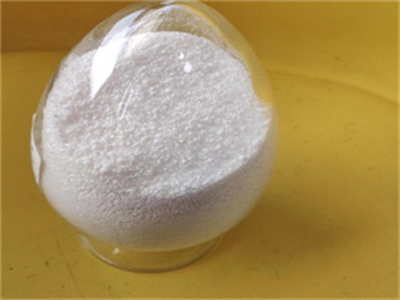

- Appearance: white granule

- CAS No.:9003-05-4073

- Type: cationic

- Formula: (C3h5no)N

- Solid Content: ≥91%

- Application:paper chemicals, rubber auxiliary agents

- Transport Package: one 20’fcl load in 15-18mt palletized

- Delivery: 5-15days after deposit

degradation of polyacrylamide and its significance in nature

high quality flocculant polyacrylamide (pam) is commonly used as a flocculant in water and wastewater treatment, a soil conditioner, and a viscosity improver and friction enhancer.

continuous low dosing of cationic polyacrylamide (pam) price,schematic diagram of algal biomass removal through polyacrylamide (pam) flocculation in 1-ha wastewater treatment high rate algal pond (hrap). display full size a conical water tank (total volume: 1.3 m 3 ) was used to make up and store as few day supply of cationic polyacrylamide (pam, crystalfloc b 490 h: 90% active ingredient cationic

polyacrylamide in water treatment enhancing efficiency flocculant

pam in wastewater treatment pam is widely used as a coagulant and flocculant in wastewater treatment. its high molecular structure effectively aggregates suspended particles in water, leading to the formation of larger clusters that are easier to settle and separate, thereby enhancing wastewater clarity and treatment efficiency.

polymer based flocculants review of water purification,for instance, in the case of kaolinite suspensions with neutral ph, any pam flocculant, independent of mw or charge type and concentration, can accomplish successful flocculation; however, only a small number of pam flocculants with very precise properties (e.g., very high mw, anionic medium charge) can stimulate flocculation of oil sands

transfer and degradation of polyacrylamide-based flocculants

the aim of this review was to summarize information and scientific data from the literature dedicated to the fate of polyacrylamide (pam)-based flocculants in hydrosystems. flocculants, usually composed of pam, are widely used in several industrial fields, particularly in minerals extraction, to enhance solid/liquid separation in water containing suspended matter. these polymers can contain

preparation and properties of cationic polyacrylamide,cationic polyacrylamide is commonly used as a flocculant in the water treatment process in industries of mining, metallurgy, textile, papermaking and so on. It is also a multipurpose chemical used in oil industry.nano-silica/cationic polyacrylamide (cpam) prepared by inverse emulsion polymerization of modified silica (c-sio2) as a hydrophobic component with acrylamide, dimethyl diallyl ammonium chloride and methacryloyloxyethyl trimethyl ammonium chloride (dmc

hot product flocculant polyacrylamide (pam)

flocculants may not be unfamiliar to professionals who have been working with water treatment, but which flocculants are there, and how to distinguish and use them correctly seems a very confusing topic among many people. flocculant is a type of substance that can reduce or eliminate the precipitation stability and polymerization stability of dispersed particles in water, and make dispersed

optimization conditions to obtain cationic polyacrylamide.he, p. synthesis of cationic polyacrylamide via inverse emulsion polymerization method for the application in water treatment. preparation and properties of cationic polyacrylamide flocculant for drilling fluid based on modified nano sio 2. j. polym.

preparation of a novel cationic polyacrylamide bioflocculant and its

the supernatant fluid and sludge produced by traditional polyacrylamide flocculant (pam) flocculation of municipal sewage emit a strong odor, and the dewatering performance of flocculant flocculating sludge based on acrylamide as the main synthetic raw material remains undesirable. in this study, we investigated a new green bioflocculant called sdf. this bioflocculant was made using 3-chloro-2

chemical polyacrylamide water treatment polymer,polyacrylamide (abbreviated as pam or paam) is a polymer with the formula (-ch 2 chconh 2-). it has a linear-chain structure. it has a linear-chain structure. pam is highly water-absorbent, forming a soft gel when hydrated.

water treatment company almasa environmental solutions

we offer unique industrial wastewater treatment solutions for the pharmaceutical, food processing, chemical, paper, and metal industries, as well as many other applications. acid-free treatment, no hazardous required. stable ph levels at 6.0 8.0. no reverse osmosis treatment required. gcc patented technology.

white powder cationic polyacrylamide for waste water treatment,high quality white powder cationic polyacrylamide for waste water treatment from china, china’s leading white powder cationic polyacrylamide product, with strict quality control 100 mesh cationic polyacrylamide factories, producing high quality polyacrylamide sewage treatment white powder products.

chemicals polyacrylamide manufacturers latest price

find here polyacrylamide, 9003-05-8 manufacturers, suppliers exporters in india. get contact details address of companies manufacturing and supplying polyacrylamide, 9003-05-8 across india.

water treatment polyacrylamide gel electrophoresis an overview,intrinsically disordered proteins. angela bekesi, peter tompa, in methods in enzymology, 2018. 2.4.1 sodium dodecyl sulfate-polyacrylamide gel electrophoresis. is the most frequently used technique to visualize protein degradation and the presence of contaminating proteins; however, in the case of cbp/p300, it has considerable limitations.

india free sample pam-nonionic polyacrylamide cost

wastewater treatment polymer pam polyacrylamide market 2019. wastewater treatment polymer pam polyacrylamide market size by types, applications, major regions and major manufacturers including the capacity, production, price, revenue, cost, gross margin, sales volume, sales revenue, consumption, growth rate, import, export, supply, future strategies.

cas no. 9003-05-8 polyacrylamide pam sewage water treatment,high quality cas no. 9003-05-8 polyacrylamide pam sewage water treatment chemicals from china, china’s leading 9003-05-8 cationic pam product, with strict quality control cationic pam sewage water treatment factories, producing high quality cas 9003-05-8 cationic polymer products.

synthesis of anionic polyacrylamide under uv initiation and its

compared with these methods, flocculation is an important eco-friendly treatment technology with lower processing cost requirements; thus, this technique has been used extensively in drinking water and wastewater treatment facilities [17]. despite its numerous advantages, removal of dop from water through coagulation–flocculation has not yet

use for water treatment chemicals manufacturer anionic flocculant,cas no.: 9003-05-08 formula: (c3h5no)n einecs: 201-173-7 acid-base polyacrylamide flocculant: 6-8 certification: wqa, iso9001 environmental protection: yes

- How is the polyacrylamide (PAM) market performing in 2024?

- Track polyacrylamide (PAM) price trends and forecasts for the top ten countries worldwide. North America, quarter ending March 2024 The North American polyacrylamide (PAM) market continued to decline in the first quarter of 2024, with prices falling to $2,375 per metric ton (FOB - Texas) by the end of March.

- How much does polyacrylamide cost in the US?

- North America The prices of Polyacrylamide declined in the USA market during the third quarter of 2022, with cost ranging at USD 2252/tonne Polyacrylamide Anionic Grade FOB Texas with a quarterly decline of 11.1% as per recorded by ChemAnalyst pricing team data.

- Why did polyacrylamide (PAM) prices increase in Q4?

- Prices of Polyacrylamide (PAM) increased effectively during this quarter across North America region, supported by firm offtakes from the downstream sectors. The demand for Polyacrylamide remained firm throughout the quarter, taking support of firm offtakes from paper pulp and water treatment sector.

- Why did polyacrylamide prices remain firm in India?

- In India, the prices of Polyacrylamide remained firm, driven by the global uptrend on the raw material front. Trade momentum remained muted amid volatile raw material prices in July and pressured demand fundamentals.