- Classification: chemical auxiliary agent

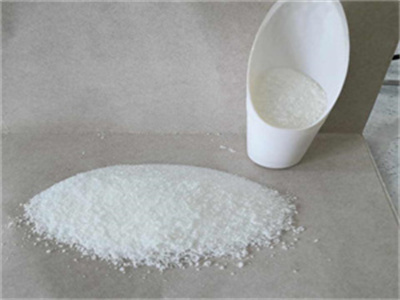

- Appearance: white powder

- CAS No.:9003-05-5262

- Type: cationic,anionic

- Formula: (C3h5no)N

- Solid Content: ≥91.5%

- Application:coal washing industries

- Transport Package: one 20’fcl load in 18-20mt for usual

- Delivery: 3-7day

anionic polymer flocculant polyacrylamide for water

how is an anionic polyacrylamide flocculant synthesized? in this study, an anionic polyacrylamide flocculant was synthesized by ultrasonic initiated template copolymerization (ustp), using sodium allylsulfonate (sas) and acrylamide as monomers, poly diallyl dimethyl ammonium chloride (polydadmac) as template, and 2,2¡ä-azobis [2- (2-imidazolin-2-yl) propane] dihydrochloride (va-044) as

uganda poly aluminium chloride pac powder for water treatment,brief introduction: polyaluminium chloride(pac) is one kind of water-soluble inorganic polymer flocculant. it ls adopting advanced manufacturing technique and high quality raw material with an appearance of yellow. product performance 1. become flocculant in high speed, big block, high activity and rapid sedimentation 2. it does’t need other accessory ingredients and use less dosage than.

recent achievements in polymer bio-based flocculants for sale

the flocculants, designed for coal slime water treatment, were characterized using the ftir, xrd and sem methods. it has been shown that water turbidity was reduced by ~97% and ~94%, while cod removal was ~78 and ~74% in the presence of fe 3 o 4 -chitosan-cellulose and fe 3 o 4 -chitosan-biochar, respectively.

polyacrylamide in water treatment enhancing efficiency flocculant,polyacrylamide (pam) plays a crucial role as a water treatment agent in various applications. this article explores the diverse applications of pam in water treatment and the advantages it brings to the table. with the increasing global water scarcity and escalating environmental pollution, efficient water treatment has become paramount.

40 tons of polyacrylamide shipped to uganda-henan secco

recently, the competitiveness of china’s chemical industry in the overseas market was further enhanced when a 40-ton batch of polyacrylamide was successfully shipped to uganda. polyacrylamide is a kind of chemical material widely used in various fields, especially in water treatment, oil field mining, textile, paper and other fields with an

polyacrylamide (pam) manufacturer,flocculant supplier,over the past 16 years, asiafloc is a polyacrylamide (pam) manufacturer,a full range of product series have been completed,including cationic polyacrylamide,anionic polyacrylamide,nonionic polyacrylamide,amphoteric polyacrylamide total over 200 different models.

high quality water treatment flocculant polyacrylamide in uganda

polyacrylamide (pam), the white granular in appearance, can be divided into three types, they are anionic polyacrylamide, cationic polyacrylamide and nonionic polyacrylamide. although these pam chemicals are mainly used for water treatment, they also have other different applications.

transfer and degradation of polyacrylamide-based flocculants.the aim of this review was to summarize information and scientific data from the literature dedicated to the fate of polyacrylamide (pam)-based flocculants in hydrosystems. flocculants, usually composed of pam, are widely used in several industrial fields, particularly in minerals extraction, to enhance solid/liquid separation in water containing suspended matter. these polymers can contain

polyacrylamide water treatment agents in uganda with high quality

classification: chemical auxiliary agent: appearance: white or slightly yellow powder: molecular weight: 12-14 million: cas no. 9003-05-8: package: one 20’fcl load in 15-18mt palletized

flocculation vs. deflocculation — what’s the difference?,flocculation is a process where suspended particles in a fluid come together to form larger clumps, or flocs, usually through the addition of a flocculating agent or under certain physical conditions. this process is often used in water treatment to remove contaminants and in industries to enhance the separation of solids from liquids.

polyacrylamide quality assured from top manufacturers

polyacrylamide is a water-soluble polymer with various industrial applications, primarily in flocculation processes. it is commonly used in water treatment, paper making, and screen printing to agglomerate solids for easier removal. polyacrylamide can be supplied in powder or liquid form, with the liquid form further categorized as solution and

how flocculation cleans up drinking water science project,to become clean and clear, the water has to undergo several treatment steps before it is safe to drink. this cleanup happens in a drinking water treatment plant. one of the first steps in a treatment plant is getting rid of the total suspended solids with a process called flocculation.

flocculants chemical water treatment nonionic anionic cationic polyacrylamide

polyacrylamide also known as flocculant, It is one of the most widely used varieties of water-soluble polymers and easy absorb to water as well as dissolving in organic solvents such as acetic acid, ethylene glycol, glycerin, and amines.

controlled release of phosphorus from super absorbent,phr and koh were mixed in acrylic acid soln. to provide phosphorus (p) and potassium (k) nutrients, resp. impacts on water absorption capacity of the super absorbent were investigated. the max. swelling capacity in distd. water or 0.9 wt.% (wt. percent) nacl soln. reached 498 g g-1 and 65 g g-1 (water/prepd. dry super absorbent) resp.

preparation and properties of cationic polyacrylamide

it is the most widely used organic synthetic flocculant, with the highest overall efficiency. despite numerous advantages, to adapt to the complex and changing drilling environment, the temperature, salt, and shear resistances and other properties need to be optimized to improve the comprehensive flocculation effect of pam [ 1 , 2 ].

quality cationic polyacrylamide cpam anionic polyacrylamide,99% purity promotion price cationic polyacrylamide cpam cas 9003-05-water treatment; white powder 99% cationic polymer flocculant sludge conditioning; high polymer cationic polyacrylamide cpam cas 9003-05-8 flocculating agents; 99% purity white powder cationic polyacrylamide cpam cas 9003-05-8

anionic polyacrylamide manufacturers, suppliers, dealers prices

discover 67 products from anionic polyacrylamide manufacturers, suppliers, distributors, and dealers across india. anionic polyacrylamide product price in india ranges from 100 to 19,500 inr and minimum order requirements from 1 to 1,000.

manufacturer oilfield additive flocculant pam bangladesh,classification: chemical auxiliary agent: appearance: white particles: molecular weight: 12-16 million: cas no. 9003-05-8: package: 900-1000kg packed in one pallet

- Can cationic polyacrylamide be used in water treatment and sludge dewatering?

- To read the full-text of this research, you can request a copy directly from the authors. Cationic polyacrylamide (CPAM) were used extensively in water treatment, enhanced oil recovery and sludge dewatering. The review summarized the synthesis methods research progress of cationic flocculants.

- Can cationic flocculants be used in sludge dewatering treatment?

- Furthermore, the paper reviewed that the application of cationic flocculants in sludge dewatering treatment. Based on these reviews, the future research perspectives of synthesis and application on cationic flocculants in sludge dewatering treatment were proposed.

- Are cationic copolymers used in sludge dewatering?

- Four groups of synthesis technologies of cationic copolymers were reviewed, including aqueous solution polymerization, dispersion polymerization, inverse emulsion polymerization and photo initiated polymerization. Furthermore, the paper reviewed that the application of cationic flocculants in sludge dewatering treatment.

- What is cationic polyacrylamide (CPAM)?

- Cationic polyacrylamides (CPAMs) are widely utilized due to their excellent performance in flocculation and sludge dewatering . Numerous studies have been conducted on CPAM synthesis technologies, including grafting, free radical polymerization, and polymer modification .