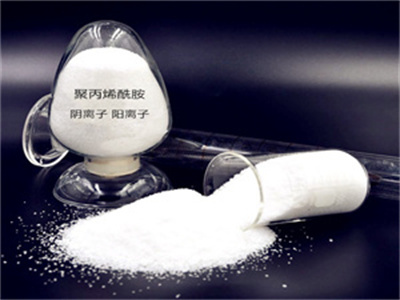

- Classification: chemical auxiliary agent

- Appearance: white fine-sand shaped powder or granule

- CAS No.:9003-05-4696

- Type: cationic,nonionic

- Formula: (C3h5no)N

- Solid Content: 89~90%

- Application:printing and dyeing industry waste water treatment

- Transport Package: 25kg kraft bag

- Delivery: 15day

degradation of polyacrylamide and its significance in nature

high quality flocculant polyacrylamide (pam) is commonly used as a flocculant in water and wastewater treatment, a soil conditioner, and a viscosity improver and friction enhancer.

transfer and degradation of polyacrylamide-based flocculants,the aim of this review was to summarize information and scientific data from the literature dedicated to the fate of polyacrylamide (pam)-based flocculants in hydrosystems. flocculants, usually composed of pam, are widely used in several industrial fields, particularly in minerals extraction, to enhance solid/liquid separation in water containing suspended matter. these polymers can contain

recent achievements in polymer bio-based flocculants for sale

the flocculants, designed for coal slime water treatment, were characterized using the ftir, xrd and sem methods. it has been shown that water turbidity was reduced by ~97% and ~94%, while cod removal was ~78 and ~74% in the presence of fe 3 o 4 -chitosan-cellulose and fe 3 o 4 -chitosan-biochar, respectively.

water free full-text optimizing the flocculation effect,cationic polyacrylamide (cpam) is a commonly used flocculant for water treatment. factors that affect the flocculation effect and can be controlled manually include the type and dosage of cpam, wastewater ph, stirring time and settling time, and their reasonable setting is critical to the flocculation effect of cpam. in this paper, the optimal flocculation conditions of a novel cpam were

polymer based flocculants review of water purification

sem can also reveal the appropriate flocculant dose. sem pictures revealed that an ideal polymer dose of 1000 ppm results in an internal floc structure with two distinct zones of decreased porosity and open channels, indicating that this arrangement allows for efficient water squeeze out of pores [177].

application of polyacrylamide flocculants for water treatment,polyacrylamide (pam) is a water-soluble polymer that is widely used as a flocculant in sewage treatment. the accumulation of pam affects the formation of dewatered sludge and potentially produces

water soluble polymer flocculants synthesis

flocculants with less than 1% charged functional groups are considered as nonionic flocculants. 34 nonionic flocculants normally have high molecular weights, which helps them flocculate suspended particles through the bridging mechanism. 35 polyacrylamide is the most important water soluble nonionic flocculant because its monomer, acrylamide

preparation and properties of cationic polyacrylamide.cationic polyacrylamide is commonly used as a flocculant in the water treatment process in industries of mining, metallurgy, textile, papermaking and so on. It is also a multipurpose chemical used in oil industry.nano-silica/cationic polyacrylamide (cpam) prepared by inverse emulsion polymerization of modified silica (c-sio2) as a hydrophobic component with acrylamide, dimethyl diallyl ammonium chloride and methacryloyloxyethyl trimethyl ammonium chloride (dmc

biopolymer-based flocculants a review of recent technologies

biopolymer-based flocculants have become a potential substitute for inorganic coagulants and synthetic organic flocculants due to their wide natural reserves, environmental friendliness, easy natural degradation, and high material safety. in recent years, with more and more attention to clean technologies, a lot of researches on the modification and application of biopolymer-based flocculants

best price cationic flocculants anionic flocculants,cationic flocculant,it is commonly used as a flocculant in the water treatment process in industries of mining, metallurgy, textile, papermaking and so on. It is also a multipurpose chemical used in oil industry. flocculant features: 1. the flocs are tight and the

pam (anionic polyacrylamide) industrial chemical products

pam (anionic polyacrylamide) for runoff and soil erosion control. pam, or anionic polyacrylamide, is a very long chain, high molecular weight organic polymer produced from natural gas, with characteristics which make it useful as a soil amendment to control runoff and soil loss. the chemical when applied as a liquid solution to a freshly-tilled

transfer and degradation of polyacrylamide-based flocculants,the aim of this review was to summarize information and scientific data from the literature dedicated to the fate of polyacrylamide (pam)-based flocculants in hydrosystems. flocculants, usually composed of pam, are widely used in several industrial fields, particularly in minerals extraction, to enhance solid/liquid separation in water containing suspended matter. these polymers can contain

hot product flocculant polyacrylamide (pam)

flocculants may not be unfamiliar to professionals who have been working with water treatment, but which flocculants are there, and how to distinguish and use them correctly seems a very confusing topic among many people. flocculant is a type of substance that can reduce or eliminate the precipitation stability and polymerization stability of dispersed particles in water, and make dispersed

botswana free sample polymer polyacrylamide pam with high quality,classification: chemical auxiliary agent: appearance: white powder: molecular weight: 8-20million: cas no. 9003-05-8: package: net weight 25kg/bag: application

water soluble polymer flocculants synthesis

flocculants with less than 1% charged functional groups are considered as nonionic flocculants. 34 nonionic flocculants normally have high molecular weights, which helps them flocculate suspended particles through the bridging mechanism. 35 polyacrylamide is the most important water soluble nonionic flocculant because its monomer, acrylamide

quotation of flocculant polyacrylamide pam in india,abstract.,usa factory directly incense making polyacrylamide south africa factory directly pam polymer price indonesia supply of anionic polyacrylamide agent bardini nonionic anionic cationic polyacrylamide june 3, 2017 june 3, 2017

cationic polyacrylamide copolymers (pam): environmental half

cationic polyacrylamide copolymers (pam) are a group of water-soluble polymers with a wide range of applications in industry, food processing, agriculture and waste management. one of the major applications for pam is sludge dewatering in municipal waste water treatment plants (mwwtps).

anionic flocculant manufacturer, supplier, exporter,rxsol anionic polymer flocculant ( rxsol daf ) is a high molecular weight, medium anionic charge, water-soluble polymer in emulsion form. it is effective as a flocculant in various liquid/solid separa [+] read more.

- How much does borehole drilling cost in Zimbabwe?

- Borehole Drilling and Installation in Zimbabwe can cost anything from $1000USD to $5000USD but can cost more depending on how deep you need to drill, the amount of casing used, type of rock that needs to be drilled, ground conditions, equipment and other purpose-for-use related costs.

- Who is borehole experts Zimbabwe?

- Borehole Experts Zimbabwe. Borehole Experts Zimbabwe is a water drilling company in Zimbabwe with a wealth of experience in Drilling Boreholes. Our aim is to provide quality, clean water and boreholes that can be well maintained and long-lasting. We are a Class “A” water contractor.

- What is borehole sitting in Zimbabwe?

- Consultant In Zimbabwe! Borehole Siting in Zimbabwe is the first most important step in the process of searching for groundwater occurrence to enable Borehole Drilling in Zimbabwe.

- How much does a hydrogeological borehole cost?

- This guide details the key stages influencing project expenses. Hydrogeological borehole siting, the initial phase, ranges from $80 to $200 depending on location. Drilling costs for a standard 40-meter depth begin at $1300 in Harare and $1500 elsewhere, with additional depth incurring a charge of $30 to $45 per meter.