- Classification: chemical auxiliary agent

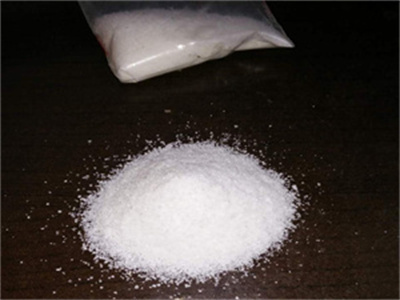

- Appearance: off-white granular powder

- CAS No.:9003-05-12781

- Type: cationic,nonionic

- Formula: (C3h5no)N

- Solid Content: ≥90.5%

- Application:oil well drilling waste water treatment polyacrylamide

- Transport Package: one 20’fcl load in 15-18mt palletized

- Delivery: 15day

understanding polyacrylamide (pam) types

polyacrylamide (pam) is a water-soluble linear polymer and one of the most widely used water-soluble polymer compounds.its derivatives find applications as efficient coagulants, thickeners, paper enhancers, and liquid friction reducers across various industries, including water treatment, papermaking, petroleum, coal, metallurgy, geology, textiles, and construction.

hot sale polyacrylamide flocculant pam for water treatment,polyacrylamide cas no.: 9003-05-8, hs code: 39069010 appearance: white powder ion type: anionic, cationic, non-ionic packaging: 25kg/Chemicals Polyacrylamide with plastic inside and woven outside description: according to the ionic characteristics, it can be divided into four types: non-ionic polyacrylamide npam, anionic polyacrylamide apam, cationic polyacrylamide cpam and amphoteric polyacrylamide.

high quality polyacrylamide pam flocculant for water treatment

polyacrylamide cas no.: 9003-05-8, hs code: 39069010 appearance: white powder ion type: anionic, cationic, non-ionic packaging: 25kg/Chemicals Polyacrylamide with plastic inside and woven outside description: according to the ionic characteristics, it can be divided into four types: non-ionic polyacrylamide npam, anionic polyacrylamide apam, cationic polyacrylamide cpam and amphoteric polyacrylamide.

the efficiency of polyaluminum chloride and anionic,the coagulation and flocculation method stands out as a widely utilized approach in industrial wastewater treatment. this study explores the application of a new sedimentation concept, focusing on one-step removal, and evaluates the effectiveness of polyaluminum chloride (pac) and anionic polyacrylamide (pam) in reducing turbidity in simulated hot-rolled steel factory effluent. the

synthesis and application of anionic polyacrylamide for water treatment

anionic polyacrylamide polymer (paam) is a commonly used synthetic polymer in the coagulation-flocculation treatment process for industrial wastewater [7]. although the coagulation-flocculation

anionic polyacrylamide pam in south africa- anionic,industrial waste water treatment 1. sludge thickening 2. dewatering 3. colour removal 4. metallurgy 5. sewage treatment for various industries such as paper making 6. mining 7. coal mining 8. petroleum u ses of polyacrylamide (pam) waste water clarifications including primary, secondary and sludge thickening dewatering applications

polyacrylamide flocculant polyacrylamide

applied polymer systems introduced flocculants to the erosion and water industries in the 1990s, drawing from decades of research and use in mining effluent treatment. anionic polyacrylamide is the most widely accepted and commonly used flocculant due to being both safe for aquatic life, and highly effective.

research on a new cationic polyacrylamide (cpam) with high quality.the cationic monomers on these microblock segments can be polymerized to form a cpamd with a new cationic microblock structure. in addition, microwave has mechanical effects such as oscillation, emulsification, and diffusion, which can accelerate the heat and mass transfer process of the reaction system, thus accelerating the reaction rate (wiesbrock et al. 2004; hoogenboom and schubert 2007

high purity cationic polyacrylamide copolymer (pam)

ester hydrolysis of the polymer side chain releases choline and anionicpam. other authors focused on the investigation of the microbial processes. for example, nakamiya and kinoshita [ 8 ] isolated two bacterial strains from soil, enterobacter agglomerans and azomonas macrocytogenes, with the ability to degrade pam.

organic polyelectrolytes in water treatment sciencedirect,cationic polymers in common use in the water industry, such as pdadmac and ech/dma, generally produce trivial amounts of dbps from chlorine when the normal levels of polymer utilised in water treatment are exposed to conventional amounts of chlorine in prechlorination (bolto, 2005). such an approach is less used these days, but is still carried

optimizing the flocculation effect of cationic polyacrylamide

cationic polyacrylamide (cpam) is a commonly used flocculant for water treatment. factors that affect the flocculation effect and can be controlled manually include the type and dosage of cpam, wastewater ph, stirring time and settling time, and their reasonable setting is critical to the flocculation effect of cpam. in this paper, the optimal flocculation conditions of a novel cpam were

polyacrylamide degradation and flocculant pam,the hydrolyzed form of polyacrylamide (hpam), a co-polymer of acrylamide and acrylic acid, is the most widely used anionic pam in oil and gas development as well as in soil conditioning.

chemical polyacrylamide (PAM) flocculant types

polyacrylamide (pam) is a water-soluble linear polymer and one of the most widely used water-soluble polymer compounds.its derivatives find applications as efficient coagulants, thickeners, paper enhancers, and liquid friction reducers across various industries, including water treatment, papermaking, petroleum, coal, metallurgy, geology, textiles, and construction.

a review of nano-based materials used as flocculants for good price,in recent years, the development of nanoparticle materials for water treatment has received great attention. from an industrial technological view point, the application of nanomaterials in the twenty-first century for water treatment will be the focal point of advanced materials design, processing and progress. in this context, the potential utilisation of different types of flocculants to

microbial degradation of polyacrylamide and the deamination

both single microbial species as well as mixed populations have been investigated for degradation. biodegradation of polyacrylamide begins with amidase catalysed deamination of polyacrylamide to ammonia and polyacrylate. the liberated ammonia is then used as a nitrogen source for growth by the microbes. the carbon backbone, polyacrylate, is

efficient near-infrared anionic conjugated polyelectrolyte,in this work, an anionic conjugated polyelectrolyte (pcp-so3k), in which the backbone contains alternating 4,4-bis-alkyl-4h-cyclopenta-[2,1-b;3,4-b′]-dithiophene and benzene structural units and the charges are provided by pendant sulfonate groups, was synthesized. the ionic nature of pcp-so3k renders it sol

chemical, pam, drilling fluid for oil field china drilling

chemical, pam, drilling fluid for oil field, find details and price about drilling fluid polyacrylamide from chemical, pam, drilling fluid for oil field wuxi lonheo