- Classification: chemical auxiliary agent

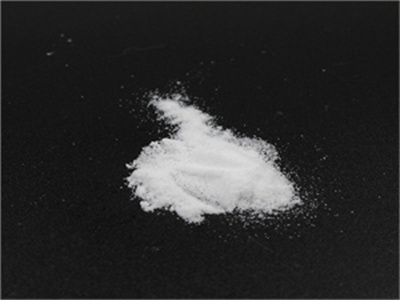

- Appearance: white or slightly yellow powder

- CAS No.:9003-05-10203

- Type: cationic,anionic

- Formula: (C3h5no)N

- Solid Content: 88%min

- Application:leather making waste water treatment

- Transport Package: 900-1000kg packed in one pallet

- Delivery: 5-15days after deposit

polyacrylamide pam flocculants water treatment industrial use

this review examines the chemical, mechanical, thermal, photolytic, and biological degradation of pam under a broad range of environmental conditions. we then consider available options for

hot sale polyacrylamide msds, polyacrylamide msds wholesale, manufacturers, price,china polyacrylamide msds wholesale select 2024 high quality polyacrylamide msds products in best price from certified chinese polyacrylamide manufacturers, water treatment polyacrylamide suppliers, wholesalers and factory flocculant pam

biodegradation of polyacrylamide and its derivatives manufacturer

some fungi and yeasts could degrade 60–80% of acrylamide. the biodegradation of pam and its derivatives are initiated by the enzyme amidase, either under aerobic or anaerobic conditions, and are further degraded partially or completely by an array of different enzymes.

microbial degradation of polyacrylamide and the deamination,polyacrylamide degradation, determined using the starch-cadmium method, was reported to be 45% under optimized conditions. growth, measured as colony forming units was also demonstrated. in addition, analyses of the culture medium by sec indicated that the high molecular weight polymer was degraded to smaller molecules during cultivation.

microbial degradation of polyacrylamide and the

biodegradation of polyacrylamide begins with amidase catalysed deamination of polyacrylamide to ammonia and polyacrylate. the liberated ammonia is then used as a nitrogen source for growth by.

polyacrylamide powder water treatment chemicals cas no. 9003-05-8,polyacrylamide powder water treatment chemicals cas no. 9003-05-8 2024 no.3. pm series: amphoteric polyacrylamide to improve paperboard manufacturing processes. 2. design of amphoteric polyacrylamide and their properties. the amphoteric polyacrylamide shown in figure 1 is water-soluble polymer prepared via radical copolymerization of acrylamide, cationic monomers, and anionic monomers.

polyacrylamide reaction distributors in kenya

polyacrylamide degradation and its implications. this requires the application of 1–20 kg of polymer per hectare (ha), 33,34 with typical mw of 1–20 × 10 6 da 21,33,35 and concentrations less than 10 mg/l; 33 the high cost of pam is a

dry strength additives polyacrylamide granules.dry strength additives. dry strength is a key quality parameter for all paper and board grades. kemira’s broad portfolio of dry strength additives include specifically designed technologies to be used with virgin, mechanical, recycled or mixed fibers and for the production of various paper, board, and tissue grades as well as molded fiber.

degradation of polyacrylamide a review semantic scholar

the results of these studies suggest that polyacrylamide can degrade to acrylamides by thermal and photolytic effects, that changes in ph do not promote the depolymerization of polyacylamide, and that gh does protect polyacrylamide and acrieslamide from environmental degradation.

water purifier anionic flocculant cationic polyacrylamide,the most common methods of demineralization water are membrane application and ion exchange resin system. our demineralized water system consists of latest 2b3t technology package called “sgx” unit. sgx is composed of cation tower, degasifier and anionic tower, which designed to produce the demineralized water up to 110 m3/hr per train.

pam chemical organic anionic polyelectrolyte cation polymer flocculant msds for sludge dewatering china cationic polyacrylamide fluccolent low cost

cas no.: 9003-05-8 formula: conh2[ch2-ch]n einecs: 231-545-4 acid-base polyacrylamide flocculant: 7-10 certification: reach, iso nsf environmental protection: yes

polyacrylamide in wastewater treatment: applications,in municipal wastewater treatment, polyacrylamide plays several key roles: (1) flocculation: pam can bind with suspended solids in the wastewater, forming larger flocs to achieve solid-liquid separation. this helps to improve sedimentation rates and reduce the burden on subsequent treatment equipment. (2) purification: pam can effectively

flocculant crystallization of precipitated calcium carbonate with anionic polyacrylamide and its application to papermaking on sale

papermaking filler, anionic polyacrylamide, carbonation summary: precipitated calcium carbonate (pcc) is widely utilized as a papermaking filler. herein, the mor-phology of pcc is controlled by

fabrication and application of cationic polyacrylamide de gruyter,cationic polyacrylamide (cpam) was prepared in aqueous solution by free radical polymerization of methacryloyloxy ethyl trimethylammonium chloride (dmc) and acrylamide. a redox initiator system was used. the structure of cpam was characterized by ir and 1 h nmr. the intrinsic viscosity and cationicity of cpam were measured by an ubbelohde viscometer and titration experiments, respectively

use of dna ladders for reproducible protein fractionation by sodium dodecyl sulfate−polyacrylamide gel electrophoresis (sds−page) for good price

in proteomics, one-dimensional (1d) sodium dodecyl sulfate−polyacrylamide gel electrophoresis (sds−page) is widely used for protein fractionation prior to mass spectrometric analysis to enhance the dynamic range of analysis and to improve the identification of low-abundance proteins. such protein prefractionation works well for quantitation strategies if the proteins are labeled prior to

polyacrylamide for industry water treatment,anionic polyacrylamide in the paper industry, polyacrylamide is used as a retention and drainage aid, enhancing the efficiency of papermaking by improving the retention of fillers, fibers, and other materials used in the paper matrix.

biodegradation of polyacrylamide by anaerobic digestion under

semantic scholar extracted view of biodegradation of polyacrylamide by anaerobic digestion under mesophilic condition and its performance in actual dewatered sludge system. by xiaohu dai et al.