- Classification: chemical auxiliary agent

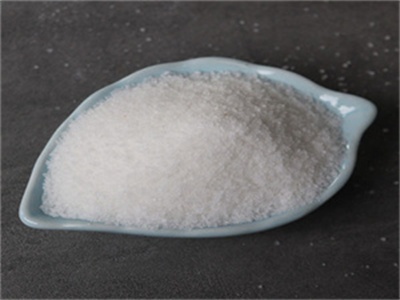

- Appearance: white crystal

- CAS No.:9003-05-6159

- Type: anionic

- Formula: (C3h5no)N

- Solid Content: ≥88.9%

- Application:chemical,papermaking industries

- Transport Package: one 20’fcl load in 15-18mt palletized

- Delivery: prompt shipment

anionic polyelectrolyte vs. cationic what’s the difference

the main difference between them lies in the type of charge they carry. anionic polyelectrolytes have negatively charged groups, while cationic polyelectrolytes have positively charged groups. this difference in charge leads to distinct properties and applications. anionic polyelectrolytes are commonly used as flocculants in water treatment

recent achievements in polymer bio-based flocculants for low cost,among the synthetic polymer flocculants, the most important is water-soluble polyacrylamide (pam)—a non-ionic, amorphous polymer which can be modified to ionic form in the copolymerization process [8,9,10]. the acrylamide monomer can be used for grafting or crosslinking of other type of polymers.

what is the difference between cationic and anionic

the main difference between cationic and anionic polyelectrolytes lies in their charges and structures in aqueous solutions. cationic polyelectrolytes have positively charged moieties and dissociate in aqueous solutions to give positively charged polyions or cations.

understanding cationic and anionic polymers: properties,applications of cationic and anionic polymers cationic. gellner’s cationic acrylic emulsion polymers are used in a wide range of printing inks in order to improve flow, gloss, and solubility. they are especially useful because they provide superior adhesion to nearly any surface, from fabric to wallpaper to various types of packaging plastic.

High quality china supplier polyelectrolyte

polyelectrolyte. chemical structures of two synthetic polyelectrolytes, as examples. to the left is poly (sodium styrene sulfonate) (pss), and to the right is polyacrylic acid (paa). both are negatively charged polyelectrolytes when dissociated. pss is a ‘strong’ polyelectrolyte (fully charged in solution), whereas paa is ‘weak’ (partially

factory supply pam cas no. 9003-05-8 anionic polyacrylamide,factory supply pam cas no. 9003-05-8 anionic polyacrylamide unexpected influence of acrylamide on clouding behavior of different from all investigated additives in literatures, acrylamide is a widely used monomer for synthesis of water-soluble polymer polyacrylamide (pam) and its hydrogel.

what is the difference between cationic and anionic

these substances play a critical role in water treatment, paper manufacturing, and numerous other applications due to their unique properties. the primary difference between cationic and anionic polyelectrolytes lies in their charge. cationic polyelectrolytes carry a positive charge, while anionic polyelectrolytes have a negative charge.

best selling customized polyacrylamide cpam water treatment polymer.polyacrylamide cpam water treatment polymer. product name: polyacrylamide cpam water treatment polymer cas no: 9003-05-8 hs code: appearance: white particles grade: fine chemical tnn specializes in food additives, pharmaceutical ingredients, cosmetic raw materials, fine chemicals, etc. please feel free to inquire if you have any needs.

anionic polyelectrolyte for various applications water treatment

caution. polyelectrolyte anionic is a high molecular weight flocculant of polyacrylamide type. it is used as a clarification and filtration agent for river water, wastewater and industrial water. with a wide application in process treatment of mining, metal amp ceramics, it is also a good clarifying agent for wastewater of textile, mining, pulp

project profile: egypt just opened the largest wastewater,egypt remains heavily dependent on the nile, and its ability to reuse water remains limited. egypt sourced less than 20% of its annual water supply from treated wastewater in 2018-2019. of the 80.25 bn cubic meters (bcm) used that year, water treatment plants provided only 13.65 bcm compared to 55.5 bcm from the nile.

research on a new cationic polyacrylamide (cpam) with high purity

the cationic monomers on these microblock segments can be polymerized to form a cpamd with a new cationic microblock structure. in addition, microwave has mechanical effects such as oscillation, emulsification, and diffusion, which can accelerate the heat and mass transfer process of the reaction system, thus accelerating the reaction rate (wiesbrock et al. 2004; hoogenboom and schubert 2007

factory supply water treatment pam polyacrylamide,this report presents a cost analysis of polyacrylamide production from acrylamide. the process examined is a typical aqueous solution polymerization. in this process polyacrylamide powder is obtained as the final product. the report examines one-time costs associated with the construction of a plant and the continuing costs associated with the

factory wholesale anionic polyacrylamide supply nonionic

factory wholesale anionic polyacrylamide supply nonionic polyacrylamide oubo detail: nonionic polyacrylamide is a high polymer with the high molecular weight and the low ion exponent, which has the function of flocculation, dispersal, thickening, bonding, film forming, gelatin and colloidal stability.

anionic polyacrylamide pam for petroleum industry to recover,what is polyacrylamide (pam) used for? this article high molecular weight polyacrylamide (pam) is commonly used as a flocculant in water and wastewater treatment, as a soil conditioner, and as a viscosity modifier and friction reducer in both enhanced oil recovery and high volume hydraulic fracturing.

polyacrylamide of wastewater treatment system

kenya among other countries experience a water crisis and it has been projected that by 2025 the drinking water availability. will lower from 548m /capita/decade to 250m /capita/decade (ndunda

anionic polyacrylamide(phpa polymer) of chinafloc a2520,anionic polyacrylamideof chinafloc a2520 is a very high molecular weight anionic polyacrylamide flocculant supplied as a free flowing granular powder. principal uses. anionic polyacrylamide of chinafloc a2520 has found application in a wide variety of mineral processing operations including the following: 1.

synthesis and application of the cationic lignin amine flocculant

cationic lignin amine flocculants were obtained by the mannich reaction of kraft lignin with formaldehyde and polyacrylamides. the cationic reaction products were tested as a flocculating agent by flocculation of reactive brilliant blue kn-r and linear alkylbenzene sulphonates in an aqueous system. the effects of flocculant dosage and ph on the flocculation performance are discussed in detail. the

flocculants and coagulants market growth analysis,the global flocculants and coagulants market size was estimated around usd 10.6 billion in 2018 and is expected to grow at a cagr of 5.5% during the forecast period.

- What is the role of polyacrylamide in the paper industry?

- In summary, polyacrylamide plays various critical roles in the paper industry, from enhancing paper properties to optimizing pulp processing. As a reputable manufacturer in China, Taoran Chemical Company serves as a reliable partner to the papermaking sector, offering top-quality products and expert application knowledge.

- Does polyacrylamide improve pulp agglomeration?

- Improving Pulp Agglomeration:In the papermaking process, polyacrylamide is employed as a coagulant and flocculant to aggregate fibers and particles, reducing suspended solids and enhancing pulp agglomeration. This leads to improved efficiency in papermaking processes.

- What is polyacrylamide used for?

- Polyacrylamide has become a versatile chemical compound widely used in various applications, including the paper industry. As a leading Chinese manufacturer of polyacrylamide, Taoran Chemical Company plays a significant role in its applications within the papermaking sector.

- Why is Taoran Chemical Company a leading manufacturer of polyacrylamide?

- As a leading Chinese manufacturer of polyacrylamide, Taoran Chemical Company plays a significant role in its applications within the papermaking sector. Enhancing Paper Strength and Texture:Polyacrylamide serves as a paper strength enhancer, improving the durability and wear resistance of paper.