- Classification: chemical auxiliary agent

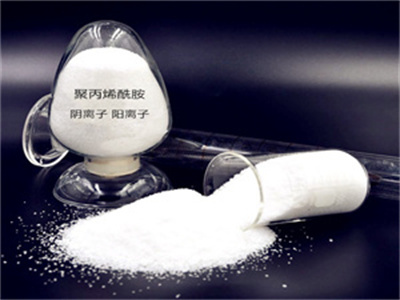

- Appearance: white powder pam

- CAS No.:9003-05-6812

- Type: anionic,cationic,nonionic

- Formula: (C3h5no)N

- Solid Content: ≥88%

- Application:oil field profile control plugging agent pam

- Transport Package: 25kg kraft paper bag

- Delivery: 3-7day

polyacrylamide pam flocculants water treatment industrial use

polyacrylamide (pam) is commonly used as a flocculant in water and wastewater treatment, as a soil conditioner, and as a viscosity modifier and friction.dissolved into 0.3% concentration and cross-linking agent added. it can be sprayed on desert to prevent and solidify sand.

high molecular weight anionic polymer flocculant polyacrylamide,it is a high performance; anionic flocculant based on a high molecular weight latex emulsion polyacrylamide co-polymer. it is scientifically formulated for use as a flocculant in effluent and wastewater treatment applications. it is designed to flocculate suspended solids and is particularly useful for non-potable raw water

cationic polyacrylamide copolymers pam water treatment chemicals

background cationic polyacrylamide copolymers (pam) are used for sludge dewatering in municipal waste water treatment and might enter the environment by spreading of the sludge on agricultural land. concern has been expressed since little is known about the degradation of pams in soils. to obtain detailed information on the polymer’s fate in the soil compartment, the degradation of 14c

polyacrylamide in water treatment enhancing efficiency for free sample,advantages of pam in industrial water treatment in industrial water treatment, pam can be used for scale inhibition and corrosion inhibition, helping to maintain the proper functioning of equipment. it can also be employed in the maintenance of cooling water systems, reducing corrosion and microbial growth while enhancing system efficiency.

best practices guidance for the use of anionic polyacrylamide

pam aids solid-liquid separation by causing suspended particles to bind and form larger aggregates. the process is known as polymer bridging. one of the most common polymer flocculants on the market. common uses of pam as a flocculant: reduction of sediment and nutrient loads to natural lakes and ponds.

hot product flocculant polyacrylamide (pam),polyacrylamide pam is currently the most widely used synthetic organic polymer flocculant, and sometimes it is also used as a coagulant aid. the raw material for the production of polyacrylamide is polyacrylonitrile ch2=chcn. under certain conditions, acrylonitrile is hydrolysed to produce acrylamide, and acrylamide is then subjected to

polyacrylamide pam flocculants water treatment industrial use

high molecular weight (106–3×107 da) polyacrylamide (pam) is commonly used as a flocculant in water and wastewater treatment,polymerized at various percentages to form anionic pam;1,4

philippine supplier cationic polyacrylamide for city sewage.apam-anionic polyacrylamide, water treatment chemical features: 1) appearance: white granule 2) molecular weight: 5 22 million minimum 3) granule: 20 kwkts0jdt8ul weblooking for polyacrylamide manufacturers and suppliers in philippines, here we listed best price polyacrylamide manufacturers and suppliers in philippines. 1 polymer 9br9bq3v2fjo

the efficiency of polyaluminum chloride and anionic

the coagulation and flocculation method stands out as a widely utilized approach in industrial wastewater treatment. this study explores the application of a new sedimentation concept, focusing on one-step removal, and evaluates the effectiveness of polyaluminum chloride (pac) and anionic polyacrylamide (pam) in reducing turbidity in simulated hot-rolled steel factory effluent. the

types of polyelectrolytes used as flocculation agents,the organic polymers provide a process of adsorption and bridging between particles as a more explicit example of flocculation process (zaharia and macoveanu, 1994; zaharia et al., 2007). cationic

synthesis and evaluation of cationic polyacrylamide for free sample

vu et al., [13] observed inorganic flocculant doses of up to 0.5 g/g of dry biomass was required for effective flocculation, resulting in high metal content in the harvested biomass. natural flocculants (e.g. chitosan, cationic polyacrylamide, and acacia tannin) have been used at doses of up to 0.3 g/g of dry biomass with culture ph adjustment [23].

supply anionic polyacrylamide/anionic pam in zambia with factory price,low price oilfield additive flocculant pam in algeria bardini polyacrylamide phpa pam july 25, 2020 july 25, 2020 polyacrylamide degradation and its npj clean water

anionic polyacrylamide flocculant, anionic polyacrylamide

pac/pam; anionic polyacrylamide (apam) anionic polyacrylamide is produced when acrylamide is polymerized with an anionic comonomer. water soluble polyacrylamide have been used for decades to facilitate solidliquid separations in wastewater and drinking water treatment, the pulp and paper industry, aquaculture, and many other industrial processes.

water filtration system manufacturers from malawi,water filtration system suppliers in malawi . giecl is a renowned supplier of water filtration system in malawi. we offer a wide range of water filtration system that are designed to meet the diverse needs of our customers. our products are made with high-quality components and advanced technology to ensure that they are reliable, efficient

polyelectrolyte water treatment chemical additives powder

the polyelectrolyte producers group (ppg) is the official association representing companies which manufacture polyelectrolytes in europe. ppg was formed to further pursue common interests in the safety of polyelectrolyte products. our purpose is to achieve increased understanding of the benefits of polyelectrolytes to society and to highlight

cheap water treatment polyacrylamide best price philippines,high purity anionic polyacrylamide 9003-05-8 in nepal wholesale pam papermaking dispersant bolivia bardini polyacrylamide polymer flocculant pam february 24, 2022 february 24, 2022

south africa wholesale agent cationic polymer for mineral

for the treatment of ink cationic acrylic polymer wastewater treatment flocculants polyacrylamide fob price: us $ 2900 / ton min. order: 18 tons cas no.:-8 formula: 02ut6my4dwpu webapr 7, 2022 · anionic polyacrylamide is mainly used in mineral processing, metallurgy, coal, food and other industries of solid-liquid separation and wastewater

- How to control flocculation?

- Flocculation should be carefully controlled, and the viscosity should not be too high to make redispersion difficult. Controlled flocculation can be achieved by a combination of control of particle size and the use of flocculating agents. The most common categories of flocculating agents are electrolytes, surfactants, and polymers. i. Electrolytes

- Which polymer is better for flocculation?

- Linear polymers (e.g., sodium carboxymethylcellulose) serve better as flocculating agents; however, coiled polymers (e.g., polyvinylpyrrolidone) are not conducive to flocculation, due to their shape and so they produce steric stability. 5. Effects of particle size on suspension stability

- Which polymer dispersion has the highest degree of flocculation?

- The degree of flocculation of the suspensions increased with increasing concentrations of MAS in all polymer and polymer–MAS dispersions used (Fig. 7 a). The SCMC-MAS dispersions showed the highest degree of flocculation, whereas the lowest degree of flocculation was obtained from the MC-MAS dispersion.

- Which polymers induce flocculation of Mas?

- The polymers used were sodium alginate (SA), sodium carboxymethylcellulose (SCMC), and methylcellulose (MC). The results showed that SA, SCMC, and MC could induce flocculation of MAS by a polymer-bridging mechanism, leading to the changes in the zeta potential of MAS and the flow properties of the polymer dispersions.