- Classification: chemical auxiliary agent

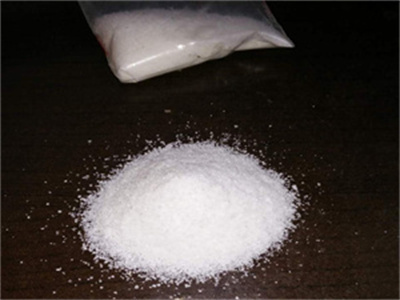

- Appearance: white/light yellow granule or powder

- CAS No.:9003-05-7712

- Type: anionic,cationic,nonionic

- Formula: (C3h5no)N

- Solid Content: ≥88%

- Application:chemical industry

- Transport Package: one 20’fcl load in 18-20mt for usual

- Delivery: 3-7day

water soluble polymer flocculants synthesis

water soluble polymer flocculants are important constituents of solid–liquid separation units for the treatment of a variety of process-affected effluents. the systematic development of a flocculant relies on a good understanding of flocculation process, polymer synthesis, polymer characterization, and, not the least, flocculation performance

anionic polyacrylamide as chemical flocculant apam,anionic polyacrylamide as chemical flocculant apam a novel method to make polyacrylamide gels with mechanical the crosslinked polyacrylamide network of the viscoelastic gel cannot be selectively activated post-polymerization.

recent achievements in polymer bio-based flocculants for low cost

polymer flocculants are used to promote solid–liquid separation processes in potable water and wastewater treatment. recently, bio-based flocculants have received a lot of attention due to their superior advantages over conventional synthetic polymers or inorganic agents.

flocculants—an ecofriendly approach journal of polymers for free sample,cationic polyacrylamide-g-polyacrylamide copolymer showed good flocculation ability, which can be used in paper industry to increase retention of filler, water drainage rate of slurry and paper strength .

cationic flocculants for paper making by alex chen jul

sinofloc offer a wide range of powder cationic polyacrylamide, as well as coagulants, to be used on paper mills and wastewater treatment plant. our cationic emulsion polymeris suitable for the.

optimization conditions to obtain cationic polyacrylamide,paper mill sludge dewatering flocculants would require cpams with a cationic degree of 10–30%. due to the short storage time of cpams, on-site mass production is preferable to importing them from overseas.

biopolymer-based flocculants a review of recent technologies

a carboxylated chitosan-based flocculant cpcts-g-p (cta-dmdaac) had a better flocculation efficiency on microcystis aeruginosa polluted water than traditional flocculants (e.g., polyacrylamide, polyferric sulfate and polyaluminium chloride).

fabricating an anionic polyacrylamide (apam) with an anionic.abstract. ultraviolet (uv)-initiated template polymerization (utp) was used as a feasible strategy to prepare a novel anionic polyacrylamide (apam) with a microblock structure. in the template copolymerization system, acrylamide and sodium allylsulfonate (sas) were used as monomers, and poly (allylammonium chloride) (paac) as a template

polymer flocculant pam fundamentals of flocculation polyacrylamide

polymer flocculant pam fundamentals of flocculation. chemistry, handling/storage, dilution water, and optimized mixing. yong kim, ph.d. practical ways to improve performance laboratory testing. george tichenor, ph.d. state-of-the-practice in biosolids/polymer blending for biosolids dewatering. david w. oerke, p.e. bcee.

factory price pam india polyacrylamide,headquartered in france,it is the largest polyacrylamide manufacturer in the world. these water soluble polymers are used in drinking water production, wastewater treatment, enhanced oil.

uganda polyacrylamide apam polymer anionic polyacrylamide

buy high quality and highly effective anionic polyacrylamide with a reasonable price from cleanwater chemicals. our factory has advanced technology and equipment at your service. if you are interested in it, welcome to

application of polyacrylamide flocculation with and without,high mw pam (low dose) with alum formed large flocs with low fractal dimension. . combined alum-high mw pam dosing produced thin and loose cake layers. . in alumpam uf systems, ammonia and phosphorus were effectively removed. abstract.

egypt high molecular cationic polyacrylamide pam flocculant

sab is a special polyacrylamide, special made to flocculant polyacrylamide pam stick industry, features with very high viscosity, less adoption, less production costs and environmental friendly. usage: mix 1kg sab with 15-50kg wood and charcoal powder, mixing for 5-8 minutes after add water, then start production.

improvement of coagulation-flocculation process using anionic,a physicochemical treatment (coagulation-flocculation) was applied to a slaughterhouse wastewater, using anionic polyacrylamide as coagulant aid to improve the settling velocity of the flocs formed with the coagulants used: ferric sulphate, aluminium sulphate and polyaluminium chloride.

polyacrylamide suppliers high quality pam products wholesale

choose us as your pam supplier, and you will get more value and services that exceed your expectations. whether you are looking for high-quality products, fair prices, customized services or free sample testing, we are here to serve you.

chemical polyacrylamide 9003-05-8 chemical supplier,anionic polyacrylamide can be used as a cytoplasm additive in the paper industry with better retention and drainage effect. it has a particularly dispersing effect for long-fiber pulp when its molecular weight is greater than 3.5 million. in addition, it can also be used as a water treatment agent.

temed thermo fisher scientific

thermo scientific pierce tetramethylethylenediamine (temed) is an essential catalyst for polyacrylamide gel polymerization. temed is used with ammonium persulfate (aps) to catalyze acrylamide polymerization when preparing gels for electrophoresis. br

- What types of flocculants are used in water treatment?

- me, cost, and safety implications.The three key classes of flocculants within the water treatment industry are powder flocculants, emulsions, and ater-based dispersion flocculants. Combined, powder and emulsion flocculants probably

- What types of flocculants does Solenis offer?

- Solenis offers a complete portfolio of emulsion, powder and water-based flocculants for water treatment and process treatment applications.

- Why do we use water based flocculants?

- roduction and treatment of metals.By stabilising with salts, water-based flocculants have a lower final vi cosity than powders and emulsions. This enables the flocculant to mix better with the particles and pollutants in the wastewate , making them preferable in highlyviscous waters and sludges such as b

- What is the best sludge dewatering flocculant?

- Best-in-class sludge dewatering flocculants, which produce higher cake dryness and therefore reduce sludge disposal costs. Our state-of-the art Praestospeed™ 120 modular dissolving system, which dissolves flocculants more rapidly and effectively than conventional equipment.