- Classification: chemical auxiliary agent

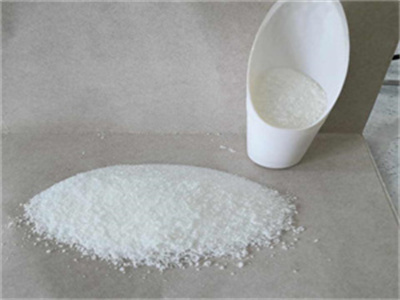

- Appearance: white powder pam

- CAS No.:9003-05-8869

- Type: nonionic

- Formula: (C3h5no)N

- Solid Content: ≥89%

- Application:papermaking industries

- Transport Package: 25kg/bag, 1000kg/bag, customized package

- Delivery: prompt shipment

recent achievements in polymer bio-based flocculants for low cost

copolymer has been obtained by ultrasonic initiated grafting of cs by acrylamide and 3-acrylamide propyltrimethylammonium chloride. this new type of flocculant has been used in combination with kaolin to enhance the flocculation efficiency.

white granule polyacrylamide pam,source wholesale white granule polyacrylamide pam quickly and easily with our company. find polymer for all areas of industrial use and order in bulk today.

transfer and degradation of polyacrylamide-based flocculants

this review summarizes the literature which gives information and scientific data on the fate of pam-based flocculants in hydrosystems. pam and associated amd have been considered, and three main families of phenomenon have been investigated: transport, adsorption, and degradation.

water treatment polyacrylamide polymer science wiley online library,a new cation-modified al-polyacrylamide (capam) flocculant was prepared by the in situ polymerization of acrylamide and (2-methacryloyloxyethyl) trimethyl ammonium chloride (dmc) with al (oh) 3 sol.

polyacrylamide pam flocculants water treatment industrial use

high molecular weight polyacrylamide (pam) is commonly used as a flocculant in water and wastewater treatment, as a soil conditioner, and as a viscosity improver, among other applications.

evaluating the effectiveness of coagulation–flocculation,the optimal requirements for the parkinsonia aculeata-hibiscus esculentus coagulation flocculation system involve adjusting the ph to 8, choosing concentrations of approximately 1.25 g l −1 and 0.6 g l −1 for the coagulant and flocculant respectively, maintaining a fast speed of 170 rpm for 3 min while keeping the slow agitation at around

optimizing the flocculation effect of cationic polyacrylamide

cationic polyacrylamide (cpam) is a commonly used flocculant for water treatment. factors that affect the flocculation effect and can be controlled manually include the type and dosage of cpam, wastewater ph, stirring time and settling time, and their reasonable setting is critical to the flocculation effect of cpam.

mention some anionic polymers used for wastewater treatment?.most of the wastewater treatment systems uses this anionic polymer (0.5 ppm) during the treatment system but noone discloses the name of this polymer. if anybody knows this polymer name, please share.

water soluble polymer flocculants synthesis

water soluble polymer flocculants are important constituents of solid–liquid separation units for the treatment of a variety of process-affected effluents. the systematic development of a flocculant relies on a good understanding of flocculation process, polymer synthesis, polymer characterization, and, not the least, flocculation performance

plastics amp polymers supplier| formulas kma sa marketing,masterbatch: we offer a broad range of colour masterbatches and pigment blends for all plastic applications. additives: range of plastic additives including anti-oxidants, uv stabilisers, lubricants and optical brighteners. supplies plastics and polymers throughout africa. a wide range: pvc, pet, styrene, tpr, tpe, hdpe, pvc, nylons and more.

polyacrylamide flocculant manufacturers in tanzania

polyacrylamide pam flocculant for water treatment chemate. excellent service. we always try our best to provide high-quality products and first-class service for all the clients. competitive price. with no the third party, you can get the best factory price from us. inquiry us to get the best polyacrylamide price now. email: [email

cationic thickener polyacrylamide,china cationic,the effective ph range of cationic polyacrylamide is 7-14, neutral and alkaline water treatment effect is good, suitable for negative charge in wastewater. such as leather factories, paper mills, municipal sewage treatment plants, special metal extraction, etc.

recent advancement of coagulation–flocculation and its

increasing environmental awareness coupled with more stringent regulation standards has triggered various industries to challenge themselves in seeking appropriate wastewater treatment technologies. coagulation–flocculation process is regarded as one of the most important and widely used treatment processes of industrial wastewaters due to its simplicity and effectiveness. this paper

lowest cost of polyacrylamide flocculants chemicals of sale,lowest cost of polyacrylamide flocculants chemicals of philippines. 1. the product should be prepared for the water solution of 0.1% as concentration. it is better to use neutral and desalted water. 2. the product should be scattered evenly in the stirring water, and the dissolving can be accelerated by warming the water (below 60℃).

pakistan: lahore water and wastewater polyacrylamide

the total capacity of the swtp will be 245,000 m3/day or 53.8 mgd. this component will also ensure that 100 percent schools/colleges in lahore are connected with safe drinking water facility. component two: investment for safe sanitation infrastructure, will include the construction of three wwtps at the locations of mahmood booti, shadbagh

cape town waste water water stories,collectively, capetonians produce hundreds of millions of litres of grey and black waste water per day. this is water from bathrooms, kitchens, toilets, and other drains. it also includes liquid waste from polyacrylamide polymer and factories, some of which is highly polluted. waste water treatment cleans dirty water until it is safe enough to release back

sustainable, low‐cost polyacrylamide

low‐cost polyacrylamide chloride‐loaded polyacrylamide,polyacrylamide finds applications in water treatment, pulp and paper production, agriculture, food processing, mining.low‐cost polyacrylamide chloride‐loaded polyacrylamide hydrogels}, author={levi hoogendoorn and mauricio huertas and phillip nitz and naiyu qi and johannes baller and carsten

- What are anionic Polyacrylamide flocculants used for?

- Today there are several anionic polyacrylamide flocculants -based products marketed for use in construction site sediment management. These products can be applied for erosion control, clarification of sediment laden runoff, and de-mucking of wet sediment during pond cleanouts.

- Which emulsion forms of anionic polyacrylamide should be avoided?

- Emulsion forms of anionic PAM should be avoided. Residual acrylamide content less than 0.05%. Top anionic polyacrylamide flocculant powder supplier, which provides efficient reliable polyacrylamide (PAM) solutions for water treatment and pulp and paper making, mineral washing.

- Who are the direct importers of polyacrylamides?

- We are the Direct Importers of Anionic, Non-Ionic Cationic Polyacrylamides. 1. Sludge thickening 2. Dewatering 3. Colour removal 4. Metallurgy 5. Sewage treatment for various industries such as paper making 6. Mining 7. Coal mining 8. Petroleum

- What is anionic polyacrylamide?

- technology-oriented and customer first. Anionic Polyacrylamide is produced when acrylamide is polymerized with an anionic comonomer. Water soluble Polyacrylamide have been used for decades to facilitate solidliquid separations in wastewater and drinking water treatment, the pulp and paper industry, aquaculture, and many other industrial processes.