- Classification: chemical auxiliary agent

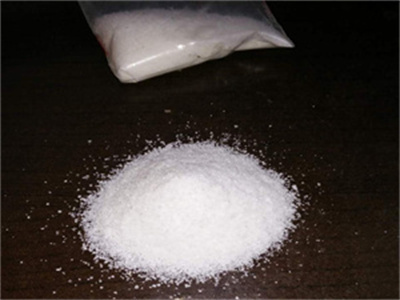

- Appearance: white granule

- CAS No.:9003-05-6810

- Type: cationic,anionic

- Formula: (C3h5no)N

- Solid Content: ≥91.5%

- Application:industrial waste water treatment

- Transport Package: 25kg kraft bag

- Delivery: 3-5day

polyacrylamide pam flocculants water treatment industrial use

polyacrylamide (pam) is commonly used as a flocculant in water and wastewater treatment, as a soil conditioner, and as a viscosity modifier and friction.dissolved into 0.3% concentration and cross-linking agent added. it can be sprayed on desert to prevent and solidify sand.

flocculant,anionic polymer flocculant,polymer water treatment,industrial/municipal applications anionic and cationic polymers。factory field support。providing application technology services.such as water treatment and pulp and paper making, mineral washing etc. various specs。

optimizing the flocculation effect of cationic polyacrylamide

cationic polyacrylamide (cpam) is a commonly used flocculant for water treatment. factors that affect the flocculation effect and can be controlled manually include the type and dosage of cpam, wastewater ph, stirring time and settling time, and their reasonable setting is critical to the flocculation effect of cpam. in this paper, the optimal flocculation conditions of a novel cpam were

cationic polyacrylamide copolymers pam water treatment chemicals,background cationic polyacrylamide copolymers (pam) are used for sludge dewatering in municipal waste water treatment and might enter the environment by spreading of the sludge on agricultural land. concern has been expressed since little is known about the degradation of pams in soils. to obtain detailed information on the polymer’s fate in the soil compartment, the degradation of 14c

trends in polyacrylamide utilization and treatment for low cost

pam plays increasingly important roles in the oil and gas industry. among a wide range of polymers, pam, and its derivatives are extensively employed in hf fluid (table 1).the usage of pam (5.6

kenya high efficiency pam anionic polyacrylamide with factory price,water treatment chemicals. areas of application. rub flock 110 ( non-ionic pam ) high molecular flocculent water treatment chemicals [for effluent treatment plants] polyelectrolyte. rub flock 110 is a high molecular weight flocculant of polyacrylamide type.

recent achievements in polymer bio-based flocculants for low cost

among the synthetic polymer flocculants, the most important is water-soluble polyacrylamide (pam)—a non-ionic, amorphous polymer which can be modified to ionic form in the copolymerization process [8,9,10]. the acrylamide monomer can be used for grafting or crosslinking of other type of polymers.

factory supply water treatment pam polyacrylamide.this report presents a cost analysis of polyacrylamide production from acrylamide. the process examined is a typical aqueous solution polymerization. in this process polyacrylamide powder is obtained as the final product. the report examines one-time costs associated with the construction of a plant and the continuing costs associated with the

differently charged polyacrylamide (pam) significantly

after cationic pam and microsand injection, the average size of ballasted floc aggregates changed from 18.1 ± 2.5 to 1122.0 ± 152.6 μm (increased by 61 times) during the phase of 120-s maturation (fig. 1 c). but for the other three cases (anionic, nonionic, and “without adding pam”), the average size of floc aggregates determined after

40% acrylamide/bis solution, 19:1 # high purity pam,description. use this 40% acrylamide/bis-acrylamide, 19:1 (5% crosslinker) solution as a faster and safer alternative to handling powdered acrylamide and bis-acrylamide. ready-to-use high-purity (99.9%) solution. reduce inhalation and contact hazards associated with weighing and preparing acrylamide and bis-acrylamide solutions.

water treatment flocculating agent pam

the water treatment flocculating agent pam are available at captivating promos that are simply irresistible. all categories. featured selections. trade assurance.

a fast silver staining protocol enabling simple and efficient,figure 2: comparison of the detection efficiency for ssr markers in tobacco and flowering chinese cabbage genotypes using different silver staining protocols. the pcr products were separated in 6% of non-denaturing polyacrylamide gels and stained using five published silver staining protocols9,11,12,13,14 and the new protocol. lane m is dna

kenya polyacrylamide pam for wastewater treatment with factory price

7. store the resulting polyacrylamide for subsequent experiments. in anticipation of experiment #3, place 100 ml of the polyacrylamide solution recovered at the end of step (6) in a 250 ml erlenmeyer flask, add 112 ml of 10% wt/vol naoh s olution in water (provided by ta).

atomic international,atomic international is a trusted name in the plumbing wholesale industry. we are one of south africa`s largest independent wholesalers of plumbing material, based in the port city of durban, on the east coast of south africa. with a legacy of over 20 years, we are committed to providing top-quality plumbing supplies to businesses in south

drilling cuttings separation drilling fluid management amp disposal

drill cuttings are particles of crushed rock produced by the grinding action of the drill bit as it penetrates into the earth. drill cuttings range in size from clay-sized particles (~ 2 μm) to coarse gravel ( 30 mm) and have an angular configuration. their chemistry and mineralogy reflect that of the sedimentary strata being penetrated by

anionic polyacrylamide polymer for water treatment,synonyms 2-propenamide, homopolymer; polyacrylamide; polyacrylamide recommended use laboratory chemicals. uses advised against food, drug, pesticide or biocidal product use. details of the supplier of the safety data sheet 2. hazard(s) identification classification classification under 2012 osha hazard communication standard (29 cfr 1910.1200)

flocculants flocculant cationic anionic polyacrylamide, inc.

polyacrylamide also known as flocculant, It is one of the most widely used varieties of water-soluble polymers and easy absorb to water as well as dissolving in organic solvents such as acetic acid, ethylene glycol, glycerin, and amines. It is divided into anionic polyacrylamide, cationic polyacrylamide and non-ionic polyacrylamide.

- What is polyacrylamide (PAM) used for?

- High molecular weight polyacrylamide (PAM) is commonly used as a flocculant in water and wastewater treatment, a soil conditioner, and a viscosity improver and friction reducer in enhanced oil recovery and high-volume hydraulic fracturing.

- Why is polyacrylamide used in water treatment?

- With the increasing global water scarcity and escalating environmental pollution, efficient water treatment has become paramount. Polyacrylamide, as a versatile polymer compound, has demonstrated significant achievements in the field of water treatment. PAM is widely used as a coagulant and flocculant in wastewater treatment.

- What is high molecular weight polyacrylamide (PAM)?

- Supplied by Our Company High molecular weight polyacrylamide (PAM) is commonly used as a flocculant in water and wastewater treatment, a soil conditioner, and a viscosity improver and friction reducer in enhanced oil recovery and high-volume hydraulic fracturing.

- Does biological filtration improve polyacrylamide biodegradation?

- Freedman, D. E. et al. Biologically active filtration for fracturing flowback and produced water treatment. J. Water Process Eng. 18, 29–40 (2017). Dai, X. et al. Waste-activated sludge fermentation for polyacrylamide biodegradation improved by anaerobic hydrolysis and key microorganisms involved in biological polyacrylamide removal.