- Classification: chemical auxiliary agent

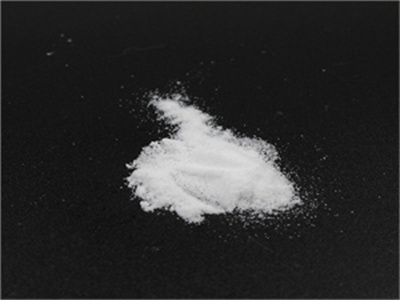

- Appearance: off-white granular powder

- CAS No.:9003-05-8480

- Type: anionic,nonionic

- Formula: (C3h5no)N

- Solid Content: ≥88.5%

- Application:sewage water treatment industry

- Transport Package: net weight 25kg/bag

- Delivery: 3-5day

polymer flocculant pam fundamentals of flocculation

polymer flocculant pam fundamentals of flocculation. chemistry, handling/storage, dilution water, and optimized mixing. yong kim, ph.d. practical ways to improve performance laboratory testing. george tichenor, ph.d. state-of-the-practice in biosolids/polymer blending for biosolids dewatering. david w. oerke, p.e. bcee.

cationic polyacrylamide guaranteed quality chemical,cationic polyacrylamide (cpam) is one of the most frequently used flocculants with high intrinsic viscosity and charge density. this flocculant is a water-soluble acrylamide-based polymer having cationic quaternary ammonium groups .

water treatment polyacrylamide 9003-05-8 price manufacturer

find here polyacrylamide, 9003-05-8 manufacturers, suppliers amp exporters in india. get contact details amp address of companies manufacturing and supplying polyacrylamide, 9003-05-8 across india.

polyacrylamide pam flocculants water treatment industrial use,high molecular weight polyacrylamide (pam) is commonly used as a flocculant in water and wastewater treatment, as a soil conditioner, and as a viscosity improver, among other applications.

best price polyacrylamide manufacturers and suppliers in india

address: 2b / bw shalimar bagh, opp. bq market, near dlf mall, new delhi, delhi , india. phone: +. plus: p544+m4 new delhi, delhi, india. innovacorp india pvt ltd is a extension of innova corporate india which are operating since 2005.

anionic polyacrylamide cas no. 9003-05-8 surfactant leader,features of anionic polyacrylamide cas no. 9003-05-8 negative charge : the anionic head group imparts water solubility and enables interaction with positively charged surfaces or particles. detergency : exceptional at removing dirt, grease, and oils due to their strong polarity and ability to penetrate and disrupt these substances.

water soluble polymer flocculants synthesis

water soluble polymer flocculants are important constituents of solid–liquid separation units for the treatment of a variety of process-affected effluents. the systematic development of a flocculant relies on a good understanding of flocculation process, polymer synthesis, polymer characterization, and, not the least, flocculation performance

choosing the right polyacrylamide flocculant pam.selecting the appropriate polyacrylamide flocculant is crucial for efficient water treatment processes. by considering factors such as water quality analysis, pam type, dosage, and.

polymer based flocculants review of water purification

polyacrylamide (pam) is the basis for most commercial polymeric flocculants mentioned in the literature (anionic, cationic, or non-ionic); this polymer is also modifiable with combinations of comonomers.

polyacrylamide companies top company list mordor intelligence,this report lists the top polyacrylamide companies based on the 2023 amp 2024 market share reports. mordor intelligence expert advisors conducted extensive research and identified these brands to be the leaders in the polyacrylamide industry.

cationic polyacrylamide production features in kenya

synergies between polyacrylamide polymerization. double distilled dust-free water was prepared using a self-made distillation setup and a g4 sinter. 2.2 plasma source and treatment conditions in this study, we used an atmospheric pressure radio frequency (rf) jet to synthesize the polymers.,polyacrylamide cationic (containing some amine functional groups) pam is used at 0.2%–0.5% on pulp

water treatment polyacrylamide supplier for south korea market,water treatment polyacrylamide supplier for south korea market. what is coagulation and flocculation in water and wastewater treatment? written by aos treatment solutions on april 3, 2018.

botswana wholesale anionic polyacrylamide agent with factory price

price : get quote packaging : 25 kg Chemicals Polyacrylamide polyacrylamide (abbreviated as pam) is a polymer formed from polyacrylamide subunits. one of the largest uses for polyacrylamide is to flocculate solids in a liquid.

polyacrylamide pam flocculant for water treatment cost,cationic pam is suitable for the treatment of wastewater with high organic colloid content in industries, such as dyeing, papermaking, food, construction, metallurgy, beneficiation, coal powder, oil field, aquatic product processing and fermentation industrial fields.

tools for sale in johannesburg water treatment marketplace

new and used tools for sale in johannesburg on facebook marketplace. find great deals and sell your items for free.

anionic polyacrylamide flocculant, anionic polyacrylamide,top anionic polyacrylamide flocculant amp powder supplier, which provides efficient amp reliable polyacrylamide (pam) solutions for water treatment and pulp and paper making, mineral washing.

study on degradation of oily wastewater by immobilized

microorganisms with biodegradable polyacrylamide and sodium the microbial method is favored for its low cost and no secondary pollution.10,11 compared with other technologies,

- What is high molecular weight polyacrylamide (PAM)?

- Supplied by Our Company High molecular weight polyacrylamide (PAM) is commonly used as a flocculant in water and wastewater treatment, a soil conditioner, and a viscosity improver and friction reducer in enhanced oil recovery and high-volume hydraulic fracturing.

- Does polymer flooding affect oil recovery rates?

- The long-term stability of HPAM has not been assessed, yet the process of polymer flooding can last many months. There is thus the potential for degradation of the polymers to cause a reduction in viscosity, and consequently oil recovery rates.

- What is polyacrylamide (PAM) used for?

- High molecular weight polyacrylamide (PAM) is commonly used as a flocculant in water and wastewater treatment, a soil conditioner, and a viscosity improver and friction reducer in enhanced oil recovery and high-volume hydraulic fracturing.

- Which polymers are used for Polymer Flooding?

- Typically synthetic polymers are used by the oil industry for polymer flooding. Historically these were unhydrolyzed polyacrylamide-based polymers, selected because of their good chemical stability. However, it became apparent that these polymers did not increase viscosity substantially and showed a high level of adsorption onto mineral surfaces.