- Classification: chemical auxiliary agent

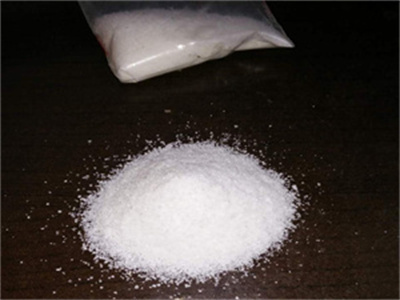

- Appearance: white crystal

- CAS No.:9003-05-7111

- Type: cationic,nonionic

- Formula: (C3h5no)N

- Solid Content: ≥90.5%

- Application:chemical,papermaking industries

- Transport Package: one 20’fcl load in 15-18mt palletized

- Delivery: 15day

polyacrylamide

polyacrylamide (abbreviated as pam or paam) is a polymer with the formula (-ch 2 chconh 2 -). it has a linear-chain structure. pam is highly water-absorbent, forming a soft gel when hydrated. in 2008, an estimated 750,000,000 kg were produced, mainly for water treatment and the paper and mineral industries. [1]

cleaning of wastewater using crosslinked poly (acrylamide-,unfortunately, the elimination of the wastewater often occurs through discharge into rivers and other effluents [5,6,7,8,9,10,11,12]. this negative situation has motivated many researchers to publish many reports in the field of the treatment of water polluted with dyes [13,14,15].

polyacrylamide pam flocculants water treatment industrial use

the hydrolyzed form of polyacrylamide (hpam), a co-polymer of acrylamide and acrylic acid, is the most widely used anionic pam in oil and gas development as well as in soil conditioning.

cationic polyacrylamide copolymers pam water treatment chemicals,14 c-radioactivity in total 3.6 g 14 cpam with a total radioactivity of 339.3 mbq was produced. the specific radioactivity was 94.25 kbq/mg. chemical structure of 14 cpam the procedures described above yielded the chemical substance as presented in fig. 1. it is important to note that the label is located on the polymer backbone of the 30 mol

polyelectrolyte polymers—types, forms, and function

polyacrylamide make up the largest group of polymers in comparison to other synthetic polymeric polyelectrolytes. the global polyacrylamide market size was valued at usd 4.5 billion in 2018 and is expected to increase to usd 6.5 billion by 2025 [9]. the primary product charge types (in the order of market size) are anionic, cationic, and

degradation and transfer of polyacrylamide based flocculent,monomers are only partially eliminated during polyacrylamide preparation and remain at the state of tracks in the end product. according to smith et al. , the residual content in monomers varies between 0.05 and 5 %. sodium acrylate presents no harmfulness like the polyacrylamide (stephens, 1991).

what are polyelectrolytes polyelectrolyte water treatment chemical additives powder

the polymer production processes are easily controlled, and economically viable. this applies also to the synthesis of acrylamide itself for which chemical and biotechnological procedures are available. polyacrylamide (pam) polymers are the solution to high quality drinking water and the efficient cleaning of waste water, they enable the

plastic granules manufacturers amp exporter in pakistan.address: 5th floor, haji adam chamber, altaf hussain road, new challi, karachi, pakistan phone: 0092-21- ,

polyelectrolyte water treatment chemical additives powder

the polyelectrolyte producers group (ppg) is the official association representing companies which manufacture polyelectrolytes in europe. ppg was formed to further pursue common interests in the safety of polyelectrolyte products. our purpose is to achieve increased understanding of the benefits of polyelectrolytes to society and to highlight

polyacrylamide manufacturer, supplier, exporter,pam wide range of applications in various industries including paper, sewage, mining, textiles we have been focusing on the export of flocculant pam (polyacrylamide/ polymer ) for more than 16 years.

wastewater production, treatment, and use in malaysia

wastewater production and treatment 2.97 billion cubic meters of wastewater generated by municipal and industrial sectors per year. dominant wastewater treatment types: preliminary primary secondary major constraints to wastewater treatment low sewerage tariff is unable to support the high operation and maintenance costs;

acrylamide prices, news, monitor, market analysis amp demand,in the usa, the overall trend has been bullish, with prices inclining over the quarter. in the first month, acrylamide prices dropped due to weak demand, especially in water treatment and paper-making sectors. severe weather disrupted operations, leading to temporary closures. paper demand fell by 2%, reflecting a broader slowdown in packaging.

polymer flocculant pam fundamentals of flocculation

emulsion: 6 months, un-opened drum/tote. dry: up to 3 years, un-opened bag. polymer solution: depends of concentration, water quality. storage temperature: 40 f 90 f. do not allow emulsion to freeze. once frozen, thaw in heated area and mix well. handling. wear latex gloves and eye protection.

polyacrylamide pam for water treatment cas no. 9003-05-8 in india,polyacrylamide pam for water treatment cas no. 9003-05-8 in india. structure of sds principle behind separation: separation of charged molecules in an electric field is based on the relative mobility of charged species which is related to frictional resistance. charge of the species: page is working upon the pr

best price polyacrylamide manufacturers and suppliers in india

looking for polyacrylamide manufacturers and suppliers in india, here we listed best price polyacrylamide manufacturers and suppliers in india. 1 innovacorp india pvt ltd address: 2b / bw shalimar bagh, opp. bq market, near dlf mall, new delhi, delhi , india phone: + plus:p544+m4 new delhi, delhi, india innovacorp india pvt ltd is a […]

1-10 tons ghana cation polyacrylamide pam price in bolivia,recent achievements in polymer bio-based flocculants. among the synthetic polymer flocculants, the most important is water-soluble polyacrylamide (pam)—a non-ionic, amorphous polymer which can be modified to ionic form in the copolymerization process [8,9,10].

flocculant anionic cationic nonionic polyacrylamide pam

high quality flocculant anionic cationic nonionic polyacrylamide pam powder price for urban sewage treatment from china, china’s leading pam chemical water treatment product, with strict quality control pam chemical water treatment factories, producing high quality pam chemical water treatment products.

- Why are polymers important in water treatment?

- Polymers play a crucial role in the enhancing performance and reducing the treatment costs of water treatment methods, particularly in adsorption and membrane filtration processes. Synthetic polymers have traditionally dominated these technologies due to their effectiveness.

- Can polymers be used for water purification?

- To date, membrane science is greatly benefitted by polymers [ , , , ]. Commercialization of fabrication and application of polymeric membrane for purification demands have evolved the environmental engineering, with a specific focus on water treatment.

- Are conductive polymers effective in wastewater treatment?

- This state-of-the-art review highlights the prime role of conductive polymers (CPs), widely known as intrinsically conductive polymers (ICPs), in wastewater treatment through reviewing very recent studies conducted on the elimination of noxious contaminations.

- Can polymers be used for membrane filtration in water purification?

- Polymers for Membrane Filtration in Water Purification. In: Das, R. (eds) Polymeric Materials for Clean Water. Springer Series on Polymer and Composite Materials.