- Classification: chemical auxiliary agent

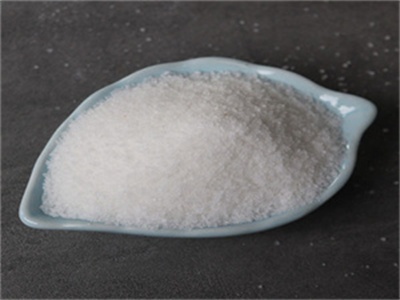

- Appearance: white crystal

- CAS No.:9003-05-2079

- Type: anionic,cationic

- Formula: (C3h5no)N

- Solid Content: ≥90%

- Application:chemical,papermaking industries

- Transport Package: 25kg/bag, 1000kg/bag, customized package

- Delivery: prompt shipment

polyacrylamide high purity pam powder

dewatered polyacrylamide emulsions differs from standard by the fact that they contain less than 6% water, with the result that the hydrogel has become almost the dry polymer itself. the consistency of the polymer is similar to plastic material. most dewatered polyacrylamide emulsions from polyacrylamide manufacturer have names starting by dw.

factory supplies cas 9003-5-8 polyacrylamide PAM,show this polyacrylamide polymer material safety data sheet to the doctor in attendance. if inhaled after inhalation: fresh air. immediately call in physician. if breathing stops: immediately apply artificial respiration, if necessary also oxygen. in case of skin contact in case of skin contact: take off immediately all contaminated water treatment. rinse skin with water

chemical flocculant PAM high quality polyacrylamide powder

polyacrylamide, anionic section 1 product and supplier identification product: polyacrylamide, anionic supplier: singletrack solutions corp address: 4838 richard road sw, calgary, alberta, canada t3e 6l1 office: 1-587-353-4119 product detail product name : anionic polyacrylamide synonyms : apam cas no.: n/a

msds anionic polyacrylamide “snow” loose,read the entire msds for a more thorough evaluation of the hazards. section 2: ingredients % osha pel acrylic acid polymer, sodium salt 90% by weight) cas no. 9003-04-7 water less than 10%) 7732-18-5 ingredients not precisely identified are proprietary or nonhazardous. values are not product specifications.

chemicals polyacrylamide chemical auxiliary agent

polyacrylamide 9003-05-8 present xupresent ke- presentpresent (6)-849 presentpresentnot present u.s. regulations polyacrylamide fda direct food additives,polyacrylamide is widely used in printing and dyeing, paper industry, mining plant, coal preparation, oil field, metallurgical industry, decorative building materials, wastewater treatment and other fields.

anionic chemical polyacrylamide atp chemicals,polyacrylamide has effects of flocculation, thickening, drag reduction, adhesive, colloidal stabilizing, filming and preventing scale. It is widely used in papermaking, mining, coal washing, metallurgy, oil exploitation and other industrial sectors and is also a important chemical for water treatment

high quality polyacrylamide cas: 9003-05-8 powder

product name : polyacrylamide product,cas-no. : 9003-05-8 1.2 relevant identified uses of the substance or mixture and uses advised against identified uses : laboratory chemicals, synthesis of substances 1.3 details of the supplier of the safety data sheet company : sigma-aldrich inc. 3050 spruce st st.

polyacrylamide polymer material safety data sheet for sale.accepta 2047 msds: water treatment flocculant: high molecular weight anionic liquid polymer polyacrylamide polymer material safety data sheet www.accepta.com date issued: 01-06-2004 accepta 2047 polyacrylamide polymer material safety data sheet product name: accepta 2047 application: water treatment flocculant: high molecular weight anionic liquid polymer

polyacrylamide polymer material safety data sheet cas no 9003-05-8

3.1 substances. cular weightcas-no.: (c3h5no)n: 71.07 g/mol : 9003-05-8 polyacrylamide pam powder. measures4.1 description of first aid meas. resif inhaledif breathed in, move person int. hing, give artificial respiration.in c. off with soap and plenty of water.in. ontactflush eyes with water as a precaution.if swall.

simple cationic polyacrylamide a drag reducer iranian,a very simple cationic monomer and a cationic hydrophobically associating polyacrylamide were synthesized, and the polymer was to function as a drag reducer. the structures of monomer and polymer were characterized by ir and nmr, and the drag-reducing rate, below and above the critical association concentration, (cac) was tested. the modified polyacrylamide is a typical hydrophobically

polyacrylamide polymer material safety data sheet walter louis

polyacrylamide polymer material safety data sheet section i walter louis chemicals 530 south 5th street, quincy, il -4896 phone: 217/223-2017 chemtrec emergency: 800/424-9300 trade name and synonyms: jy3u4 anionic emulsion polymer chemical name and synonyms: anionic polyacrylamide proper shipping name: environmentally hazardous substance, liquid, n.o.s.

optimization conditions to obtain cationic polyacrylamide,the synthesis of cationic polyacrylamide (cpam) with the desired cationic degree and molecular weight is essential for various industries, including wastewater treatment, mining, paper, cosmetic chemistry, and others. previous studies have already demonstrated methods to optimize synthesis conditions to obtain high-molecular-weight cpam emulsions and the effects of cationic degrees on

anionic polyacrylamide apam flocculant for sale in polyacrylamide

adsorption performance of anionic pam plays an important role in this process, and the dehydration efficiency can reach 75%. anionic polyacrylamide is a popular soil flocculant, often used to prevent soil erosion in cultivated land. anionic polyacrylamide polymer can be used for silt management on construction sites.

optimization conditions to obtain cationic polyacrylamide,1. introduction. industrial wastewater comprises various components, including suspended solids, dissolved ions, and organic and inorganic particles, among others.

pam polyacrylamide for water and wastewater treatment

yasa et is supplier of three different kinds of pam: non-ion polyacrylamide (npam), cationic polyacrylamide (cpam), and anionic polyacrylamide (apam). click here to learn more. pam chemical compounds are used to flocculate and coagulate suspended solids in water, wastewater, and soil. they assist in management of the earth’s soil and water.

drilling mining apam anionic polyacrylamide powder,high quality drilling mining apam anionic polyacrylamide powder from china, china’s leading apam anionic polyacrylamide powder product, with strict quality control mining anionic polyacrylamide powder factories, producing high quality cas 9003 5 8 products.

flocculant anionic polyacrylamide in paper making

4, paper-making industry for the clarification of liquid caustic soda, fiber dispersing agent, can improve the beating, the filler retention agents, paper strengthening agent, can be used to improve the treatment rate and the white water recovery;

simultaneous thermal analysis of cationic, nonionic flocculant,polyacrylamide (pam) and its derivatives are the most commercially available water-soluble polymers and are frequently used for the production of clay-polymer composites. the characterization of their thermal behavior and decomposition was carried out mainly under reduced conditions by using n sub 2 /sub …

- What are organic flocculants used for?

- Organic flocculants are widely used in a variety of industries, including oil and gas, where they help separate oil from water in produced water treatment, and in mining, where they aid in tailings management and the removal of suspended solids from process water.

- How do flocculants work in water treatment?

- The most common flocculants used in water treatment are polyacrylamides, which are synthetic polymers that have a high molecular weight. Here is a simplified explanation of how flocculants work in water treatment: Coagulants are added to water to neutralize the charges on the particles.

- What type of flocculant should I use?

- The choice of flocculant depends on the specific application. For example, inorganic flocculants are typically used in water treatment, while organic flocculants are typically used in wastewater treatment. Here are some additional benefits of flocculation:

- How do I choose the right flocculant?

- Several factors need to be considered when choosing the right flocculant, such as the type and concentration of impurities present in the water, water pH, temperature, and the desired outcome of the treatment process. In some cases, a combination of flocculants can be used to achieve optimal results.